2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

In today's rapidly evolving manufacturing landscape, high precision machining stands at the forefront of innovation, driving unprecedented advancements in efficiency and accuracy. As industries strive for excellence and competitiveness, the adoption of cutting-edge technologies has become imperative. This article delves into the top five trends and technologies set to revolutionize high precision machining by 2025, highlighting their transformative potential for the manufacturing sector.

As we navigate the complexities of modern production demands, it is essential to recognize the pivotal role that high precision machining plays in enhancing product quality and operational efficiency. The integration of automation, data analytics, and advanced materials not only streamlines processes but also reduces waste, ultimately contributing to a more sustainable manufacturing ecosystem. The exploration of these trends will provide valuable insights into how manufacturers can leverage high precision machining to stay ahead in an increasingly competitive global market.

By understanding these emerging trends, industry leaders can make informed decisions to invest in technologies that will elevate their production capabilities. The future of manufacturing is bright, and high precision machining is at the heart of this transformation, promising to redefine standards and expectations in the years to come.

The Rise of Automation and Robotics in High Precision Machining

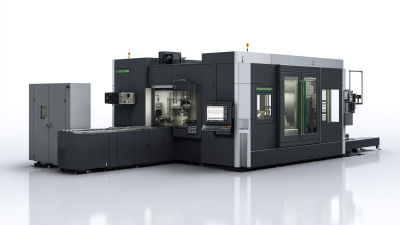

The integration of automation and robotics into high precision machining is transforming the manufacturing landscape, driving efficiency and precision to unprecedented levels. As industries increasingly demand tighter tolerances and faster production rates, robotics are playing a pivotal role. Advanced robotic systems are not only capable of performing repetitive tasks with high accuracy, but they also have the capacity to learn and adapt to dynamic production environments. This adaptability is essential for handling complex operations and variations in machining processes.

Moreover, automation technologies, including the Internet of Things (IoT) and artificial intelligence (AI), enhance the capabilities of robotic systems by providing real-time data analysis and predictive maintenance. These advancements allow for improved decision-making and operational efficiency. With autonomous machining cells capable of executing intricate tasks without human intervention, manufacturers can minimize downtime and optimize resource utilization. Consequently, the rise of robotics in high precision machining is not merely about replacing human labor; it represents a significant leap towards smarter, more efficient manufacturing processes that can keep pace with industry demands.

2025 High Precision Machining Trends

As we approach 2025, the landscape of high precision machining is evolving dramatically. The following chart illustrates the top 5 trends impacting the industry, focusing on automation and robotics, which are set to lead the transformation in manufacturing processes.

Emerging Materials and Their Impact on Machining Efficiency

The landscape of high precision machining is rapidly evolving with the advent of emerging materials that are significantly enhancing machining efficiency. According to a report by Grand View Research, the global advanced materials market is expected to reach $1 trillion by 2025, driven largely by the demand for lightweight and high-strength materials in manufacturing sectors like aerospace and automotive. These materials, such as carbon fiber composites and titanium alloys, offer improved performance characteristics that require specialized machining techniques to optimize their advantages.

Incorporating these advanced materials into manufacturing processes not only enhances the final product's durability and weight efficiency but also presents new challenges and opportunities for machining technologies. For instance, research from the International Journal of Machine Tools and Manufacture highlights that the use of these materials can increase tool wear rates significantly. This necessitates the development of advanced cutting tools made from carbide and ceramic composites, which can withstand harsher cutting conditions and maintain precision over longer periods. As manufacturers adapt to these changes, they are also exploring innovations in machining processes, such as additive manufacturing and hybrid techniques, to maximize the benefits of these emerging materials, fostering a new era of manufacturing excellence.

The Role of AI and Machine Learning in Enhancing Precision Manufacturing

The integration of AI and machine learning into precision manufacturing is transforming the landscape of high precision machining. These technologies are enabling manufacturers to enhance accuracy, reduce waste, and significantly improve overall efficiency. By leveraging vast amounts of data from various stages of the manufacturing process, AI algorithms can identify patterns and predict potential issues before they become significant problems. This predictive maintenance not only minimizes downtime but also extends the lifespan of expensive machinery.

Moreover, machine learning algorithms are continually evolving, allowing them to adapt to new challenges and complexities within the manufacturing environment. As they process data from sensors and machines in real-time, they can optimize machining parameters on the fly, ensuring that each component is produced within the desired tolerance levels. This level of automation not only boosts productivity but also delivers higher quality products, meeting the growing demand for precision in various industries. Ultimately, the collaboration between human expertise and advanced technology will pave the way for a new era of manufacturing, where precision and efficiency go hand in hand.

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

| Trend/Technology | Description | Impact on Precision Machining | Adoption Rate (2025) |

|---|---|---|---|

| AI-Powered Predictive Maintenance | Utilization of AI algorithms to predict machine failures and optimize maintenance schedules. | Increases uptime, reduces delays, and significantly cuts maintenance costs. | 65% |

| Advanced Materials | Use of high-performance materials such as composites and alloys that require precise machining. | Enhances durability and performance of machined products. | 70% |

| Robotic Automation | Implementation of robots for machining processes to increase speed and consistency. | Improves production efficiency and reduces human error. | 50% |

| Additive Manufacturing Integration | Combining traditional machining with 3D printing technologies for complex components. | Enables the production of sophisticated geometries previously difficult to achieve. | 55% |

| Real-Time Data Analytics | Using IoT sensors and data analytics to monitor machining processes in real-time. | Enhances decision-making for quality control and process optimization. | 60% |

Sustainability Trends: Eco-Friendly Practices in High Precision Machining

In the evolving landscape of high precision machining, sustainability has emerged as a critical focus. Manufacturers are increasingly adopting eco-friendly practices to reduce their environmental footprint. Techniques such as utilizing biodegradable lubricants and implementing energy-efficient machinery not only promote sustainability but also enhance operational efficiency. These practices contribute to a cleaner production environment and foster a positive corporate image, making sustainability a win-win for businesses and the planet.

Tips: Consider evaluating your current machining processes for potential waste reductions. Implementing a closed-loop system can greatly minimize raw material waste while improving recycling efforts. Additionally, investing in renewable energy sources, such as solar or wind power, can significantly cut down on energy costs over time.

Another trend in sustainable high precision machining is the incorporation of smart technology. Using IoT devices can optimize resource usage and monitor machine performance in real-time, leading to lower energy consumption and less material waste. As we move towards 2025, the integration of such technologies will be essential for manufacturers aiming to meet eco-friendly standards while remaining competitive.

Tips: Regularly assess your machinery's efficiency through performance analytics, and be open to upgrading to newer, greener technologies. Attending industry seminars or workshops focused on sustainable machining may also provide valuable insights into innovative practices that can be implemented in your operations.

Advancements in CNC Technology Driving Precision and Productivity Improvements

The landscape of manufacturing is experiencing a seismic shift, driven largely by advancements in CNC (Computer Numerical Control) technology. Recent reports estimate that the global CNC machine market is poised to reach approximately $100 billion by 2025, growing at a CAGR of about 7.5%. This growth is fueled by the demand for higher precision and efficiency in machining processes. Innovations in CNC systems, such as adaptive control algorithms and enhanced user interfaces, are enabling manufacturers to produce intricate components with unparalleled accuracy, significantly reducing waste and increasing throughput.

Moreover, the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies into CNC operations is creating smarter machining environments. According to a study by the International Federation of Robotics, about 30% of manufacturing companies are expected to implement AI-driven CNC systems by 2025. These systems are capable of real-time monitoring and predictive maintenance, which not only enhances productivity but also minimizes downtime. By harnessing these sophisticated technologies, manufacturers can achieve tighter tolerances and improve overall operational efficiency, effectively revolutionizing precision machining in the manufacturing sector.

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

Exploring High Precision Machining: Innovations Driving a $90 Billion Industry

-

How to Choose the Best Precision CNC Machining Services for Your Projects

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing