Top 10 Benefits of Using 5 Axis CNC Machines for Manufacturing Innovation

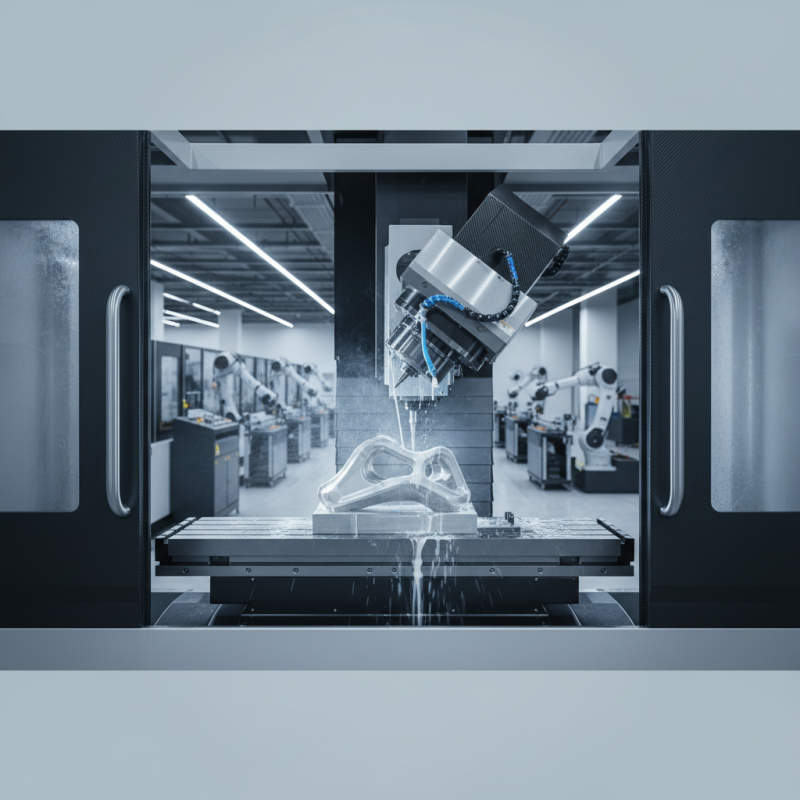

In the ever-evolving landscape of manufacturing, innovation is paramount to staying competitive and meeting the diverse demands of the market. Among the cutting-edge technologies making significant strides in this realm is the 5 axis CNC machine. This advanced machinery is revolutionizing the way manufacturers approach complex machining tasks, offering unparalleled precision and flexibility. As industries increasingly seek to produce intricate geometries and high-quality components, understanding the benefits of 5 axis CNC machines becomes crucial for fostering innovation and enhancing productivity.

The versatility of the 5 axis CNC machine allows for the simultaneous manipulation of multiple axes, enabling the creation of complex parts in a single setup. This capability not only reduces production time but also minimizes the risk of errors associated with multiple setups. As manufacturers capitalize on these efficiencies, they can achieve greater design freedom and shorten lead times, positioning themselves at the forefront of technological advancement. In this article, we will explore the top 10 benefits of integrating 5 axis CNC machines into manufacturing processes, illuminating how this technology can drive growth and elevate operational excellence in various industries.

Understanding 5 Axis CNC Machines in Modern Manufacturing

5 Axis CNC machines represent a significant advancement in modern manufacturing, enabling manufacturers to achieve higher precision and efficiency. Unlike traditional CNC machines that operate on three axes, 5 Axis machines can move along five different axes simultaneously. This capability allows for more complex geometries and intricate designs to be produced with minimal setup changes. As industries increasingly demand faster production times and greater design flexibility, the use of 5 Axis CNC technology has become a cornerstone for innovation.

In addition to improving design possibilities, 5 Axis CNC machines reduce the number of tool changes and setups required during the manufacturing process. This not only streamlines production but also enhances the quality of the finished product, as fewer handling steps lead to less potential for human error or damage. Furthermore, the ability to access hard-to-reach areas of a workpiece means that manufacturers can produce parts that were previously impossible to machine effectively, opening new avenues for product development and enhancing competitiveness in the market. Overall, the implementation of 5 Axis CNC technology significantly transforms the landscape of modern manufacturing, paving the way for unprecedented levels of innovation and efficiency.

Top 10 Benefits of Using 5 Axis CNC Machines for Manufacturing Innovation

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Enhanced Precision | 5 axis CNC machines can operate on all five sides of a component, allowing for intricate designs and fine details. | Increases product quality and reduces rework. |

| Reduced Setup Times | The ability to perform multiple cuts in one setup minimizes downtime. | Enhances productivity and reduces labor costs. |

| Versatility | Capable of working with a variety of materials, including metals, plastics, and composites. | Allows for a wider range of projects and applications. |

| Complex Geometry | Easily handles complex geometries that traditional machines can't. | Expands design capabilities and innovation. |

| Improved Tool Life | Enhanced cutting paths reduce wear on tools. | Reduces costs associated with tool replacement. |

| Better Material Utilization | Allows for optimization of cutting paths to minimize waste. | Lower material costs and more sustainable practices. |

| Automation and Integration | Can be easily integrated with automated systems and software. | Increases efficiency and streamlines operations. |

| Enhanced Surface Finish | Produces smoother surfaces due to advanced machining capability. | Reduces need for secondary finishing processes. |

| Scalability | Easily adjustable for different production volumes. | Supports business growth and changing demands. |

| Cost-effectiveness | Initial investment is offset by savings in labor and materials. | Improves overall profitability of manufacturing processes. |

Enhanced Precision and Accuracy with 5 Axis Machining

The advent of 5-axis CNC machining has transformed the landscape of manufacturing, primarily due to its enhanced precision and accuracy. Traditional 3-axis machines limit movement to three coordinates, which often necessitates multiple setups and lengthy part production times. However, 5-axis machines allow for simultaneous movement along five axes, drastically reducing the number of setups required. According to a report by the International Federation of Robotics, the precision of parts produced using 5-axis machining is notable, with some industries reporting accuracy improvements of up to 50%. This precision is crucial, especially in sectors such as aerospace and medical device manufacturing, where tolerances can be as tight as ±0.001 inches.

Moreover, 5-axis machining enables the production of complex geometries that are increasingly demanded by modern engineering applications. The ability to machine components at various angles enhances the surface finish and detail of the final product, reducing the need for secondary operations. A study published by the Manufacturing Technology Association indicates that companies utilizing 5-axis CNC machines have experienced up to a 30% reduction in overall machining time while maintaining superior quality standards. This efficiency not only boosts productivity but also aligns with the industry's shift towards lean manufacturing practices, where minimizing waste and maximizing output are paramount. Therefore, the integration of 5-axis CNC technology is not just a trend but a vital innovation for companies aiming to stay competitive in an evolving market.

Top 10 Benefits of Using 5 Axis CNC Machines for Manufacturing Innovation

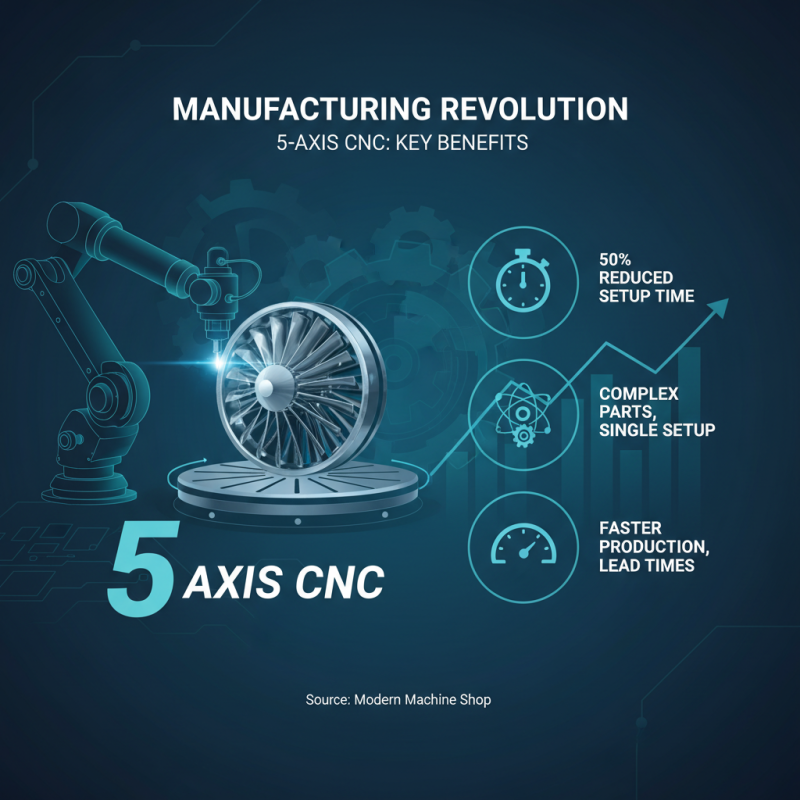

Increased Production Efficiency through Multi-Axis Operations

The trend towards multi-axis machining, specifically with 5-axis CNC machines, has revolutionized the manufacturing industry by significantly enhancing production efficiency. According to a report by the Modern Machine Shop, incorporating multi-axis CNC machines can streamline operations by reducing setup times by up to 50%. This reduction is primarily due to the machines' ability to perform complex tasks in a single setup, minimizing the need for repositioning and recalibration. As a result, manufacturers are capable of producing precision parts with intricate geometries much faster than traditional 3-axis machines, leading to increased throughput and shorter lead times.

Moreover, the versatility of 5-axis CNC machines allows manufacturers to tackle a wide range of materials and designs without compromising quality. A study in the Journal of Manufacturing Science and Engineering highlighted that manufacturers leveraging 5-axis technology reported a 30% increase in part accuracy, further enhancing product quality while simultaneously lowering waste due to reduced machining errors. This enhanced capability not only boosts operational efficiency but also gives companies a competitive edge in a rapidly evolving market, setting standards for innovation and quality that are becoming increasingly paramount in the manufacturing sector.

Versatile Material Processing Capabilities of 5 Axis CNC

The versatile material processing capabilities of 5-axis CNC machines significantly enhance their value in modern manufacturing. Unlike traditional 3-axis milling machines, which are limited in their movements, 5-axis machines can manipulate tools along five different axes, allowing for more complex geometries and intricate designs. This flexibility enables manufacturers to work with a variety of materials, including metals, plastics, and composites, opening up new avenues for innovative product development. The ability to machine parts from multiple angles without requiring repositioning reduces setup times and improves accuracy, resulting in higher quality components.

Additionally, the use of 5-axis CNC technology allows for the production of components with intricate features that cannot be easily achieved using conventional methods. From aerospace components to medical devices, the precision and adaptability of 5-axis machines make them invaluable in sectors demanding high-performance and precision-engineered parts. The advanced capabilities of these machines not only streamline the manufacturing process but also expand design possibilities, empowering engineers and designers to push the boundaries of creativity and innovation. By optimizing material usage and minimizing waste, 5-axis CNC machines contribute to more sustainable manufacturing practices, making them an essential tool for the future of the industry.

Cost-Effective Solutions and Reduced Waste in Manufacturing

The advancement of 5-axis CNC machines has become a game-changer in modern manufacturing, particularly when it comes to cost-effectiveness and waste reduction. According to a report by the International Federation of Robotics, the integration of advanced CNC technology can increase manufacturing efficiency by up to 50%. This significant boost in productivity is largely attributed to the ability of 5-axis CNC machines to perform intricate cuts and complex shapes in a single setup, minimizing the need for multiple setups and tooling changes. This translates to reduced labor costs and shorter production cycles, enabling manufacturers to respond to market demands more swiftly.

Moreover, 5-axis CNC technology plays a crucial role in minimizing material waste. A study by the Manufacturing Technology Centre indicates that companies utilizing this technology experience a 20-30% reduction in raw material waste compared to traditional machining methods. This is largely due to the precision and accuracy offered by 5-axis machines, which allow for more efficient use of materials and lower scrap rates. The ability to achieve tight tolerances means that less material needs to be discarded, thus fostering a more sustainable manufacturing process while also improving the bottom line. Overall, these advancements not only lead to substantial cost savings but also contribute to a more environmentally responsible approach to manufacturing.

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Right CNC Machine for Your Manufacturing Needs

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

How to Choose the Best Precision CNC Machining Services for Your Project

-

Why Accurate CNC Machine Quotations Are Essential for Cost-Effective Manufacturing

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications