Top 10 Benefits of Prototype Manufacturing for Your Business Success

In today's rapidly evolving marketplace, businesses are constantly seeking innovative strategies to enhance their product development processes and stay ahead of the competition. One key approach that has gained significant traction is prototype manufacturing. This methodology, which involves creating a preliminary version of a product to test and refine ideas before full-scale production, offers numerous benefits that can profoundly impact a company's success.

Prototype manufacturing not only aids in identifying potential design flaws early on but also facilitates effective communication among stakeholders, ensuring that every aspect of the product meets market demands. By utilizing this approach, businesses can reduce time-to-market, minimize costs, and improve overall product quality. Furthermore, the iterative nature of prototype manufacturing allows companies to adapt to consumer feedback more efficiently, ultimately leading to more innovative and market-ready products.

In this article, we will explore the top ten benefits of prototype manufacturing, highlighting how this essential practice can not only streamline operations but also drive growth and success in today's competitive business landscape.

Benefits of Prototype Manufacturing in Reducing Time-to-Market for New Products

Prototype manufacturing plays a critical role in significantly reducing the time-to-market for new products. By creating tangible models of designs, businesses can quickly identify flaws and make necessary adjustments before full-scale production begins. This iterative process allows for rapid testing and feedback, ensuring that products are not only viable but also align with market needs. A well-executed prototype can lead to informed decision-making and faster iterations, ultimately compressing the development cycle.

Moreover, using prototypes enables companies to engage stakeholders early in the process. This early involvement can cultivate valuable insights from potential customers and investors, which can drive improvements and increase confidence in the final product. Consequently, businesses that prioritize prototype manufacturing can launch their products sooner, gaining a competitive advantage. Fast-tracking product development not only meets consumer demands quickly but also keeps companies agile in an ever-evolving marketplace, fostering innovation and growth.

Cost Savings from Iterative Design in Prototype Development Processes

Cost savings are a critical advantage of prototype manufacturing, particularly through the iterative design processes. By investing in prototypes, businesses can identify design flaws and functionality issues early in the development phase. This approach minimizes the risk of costly errors that could arise during full-scale production. Each prototype serves as a learning opportunity, allowing teams to refine specifications and make necessary adjustments without the expense of producing a final product that may not meet market needs.

Moreover, the iterative nature of prototype development fosters innovation while keeping expenses in check. Each iteration allows designers and engineers to test new ideas and gather valuable feedback from stakeholders and potential users. This leads to better-informed decisions, reducing the likelihood of expensive revisions later in the product lifecycle. By focusing on continuous improvement, businesses can streamline their processes, enhance product quality, and ultimately achieve a more cost-effective pathway to successful market entry. The savings realized from this method not only lower manufacturing costs but also position companies more competitively in their respective industries.

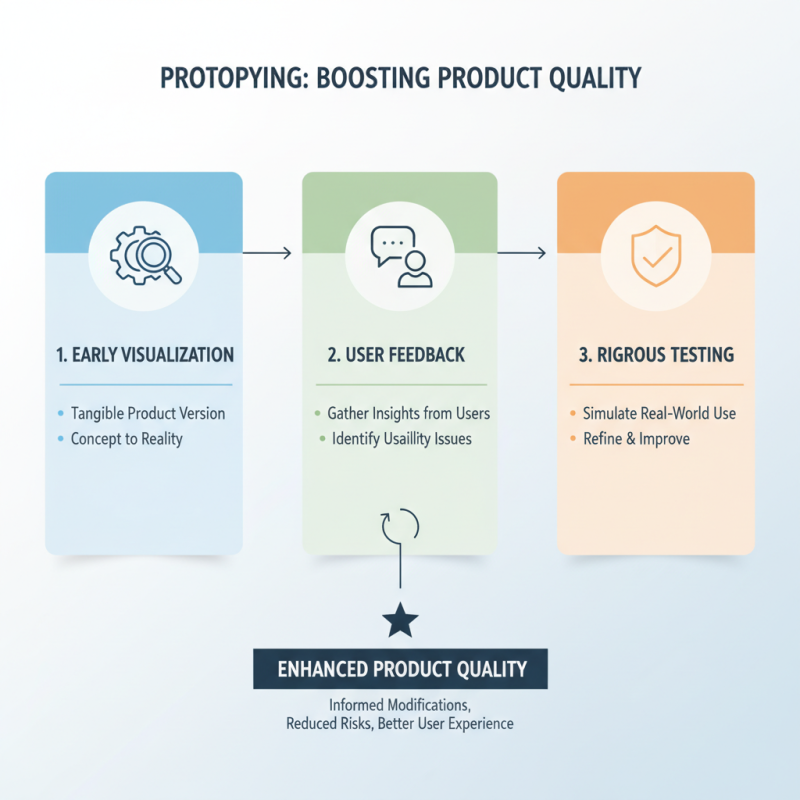

Improved Product Quality Through User Feedback and Testing in Prototyping

Prototyping plays a crucial role in enhancing product quality, primarily through the facilitation of user feedback and rigorous testing. By creating a tangible version of a product, businesses can engage potential users early in the development process. This interaction allows designers and engineers to gain valuable insights into how the product functions in real-world scenarios. Observing users as they interact with the prototype can highlight areas of confusion, inefficiency, or dissatisfaction, enabling teams to make informed modifications before final production.

Moreover, iterative testing of prototypes fosters an environment of continuous improvement. Each round of feedback provides new information that can refine design elements, resulting in a product that better meets user needs. The process not only identifies flaws but also uncovers opportunities for innovation, ultimately leading to a higher-quality end product that stands out in the marketplace. By prioritizing user feedback within the prototyping phase, businesses can significantly reduce the risk of costly redesigns and improve customer satisfaction, paving the way for greater long-term success.

Enhanced Collaboration Among Teams with Physical Prototype Demonstrations

Physical prototypes play a crucial role in enhancing collaboration among teams during the product development process. By providing a tangible representation of ideas and functionality, prototypes facilitate clearer communication and understanding across diverse groups. Team members from design, engineering, marketing, and other departments can gather around a physical model, allowing them to visualize the product, discuss features, and identify potential issues early in the development cycle. This hands-on approach minimizes misunderstandings and ensures that everyone is aligned toward a common goal.

Tips for effective collaboration with physical prototypes include setting aside dedicated time for team reviews. Schedule regular prototype demonstrations where team members can interact with the model and provide feedback in real-time. This encourages open dialogue and creative problem-solving. Additionally, it’s beneficial to document feedback and insights gathered during these sessions to track changes and ensure that all voices are considered in the decision-making process.

Creating an environment that prioritizes collaboration can significantly impact productivity and innovation. Encourage cross-functional brainstorming sessions where teams can explore various design elements of the prototype. By fostering a culture of collaboration around physical prototypes, businesses can enhance their development process, leading to more successful products that meet market needs.

Top 10 Benefits of Prototype Manufacturing for Your Business Success

| Benefit | Description | Impact on Business |

|---|---|---|

| Enhanced Collaboration | Facilitates teamwork through shared physical models, allowing clearer communication of design ideas. | Improved alignment among teams, leading to faster decision-making processes. |

| Reduced Development Time | Initial designs can be evaluated quickly through prototypes, shortening the feedback loop. | Accelerated time to market with refined products. |

| Cost Efficiency | Identifies design flaws early in the process which can save on expensive changes later. | Lower overall project costs, maximized resource allocation. |

| User Testing and Feedback | Real user interaction with prototypes delivers actionable insights for improvement. | Better product-market fit, higher customer satisfaction. |

| Risk Mitigation | Prototypes allow for testing ideas before full-scale production, reducing project risks. | Increased confidence in product launches. |

| Market Validation | Prototypes can be used to gauge consumer interest and validate concepts before investment. | Helps prioritize product features that resonate with the target audience. |

| Improved Quality | Repeated testing of prototypes leads to higher quality end products. | Enhanced brand reputation through quality assurance. |

| Innovation and Creativity | Prototyping encourages creative problem solving and innovative thinking. | Fosters a culture of innovation within the organization. |

| Sales and Marketing Strategy | Physical prototypes can be leveraged in presentations and marketing campaigns. | Increased interest and potential sales prior to product launch. |

| Documentation and Compliance | Prototyping provides a clear reference for documentation and compliance requirements. | Streamlined processes for regulatory approvals. |

Increased Competitiveness by Leveraging Advanced Prototyping Technologies

Leveraging advanced prototyping technologies is crucial for businesses aiming to enhance their competitiveness in today’s fast-paced market. These technologies, including 3D printing, CNC machining, and virtual prototyping, enable companies to create accurate and functional prototypes rapidly. By utilizing these state-of-the-art methods, businesses can significantly reduce their time-to-market for new products, allowing them to respond swiftly to customer demands and industry trends. This agility not only improves a company’s standing but also fosters a culture of innovation that can propel long-term growth.

Moreover, advanced prototyping technologies facilitate improved collaboration and communication across teams. With digital prototypes, stakeholders can visualize and interact with a product before it goes into production, ensuring that feedback is integrated early in the development process. This iterative approach minimizes costly mistakes and enhances product quality, ultimately leading to greater customer satisfaction. By investing in these technologies, businesses position themselves to not only meet but exceed market expectations, establishing a strong competitive edge in their respective fields.

Top 10 Benefits of Prototype Manufacturing for Your Business Success

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Best Precision CNC Machining Services for Your Projects

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing