Top 5 Benefits of Brass Machining for Precision Engineering Solutions

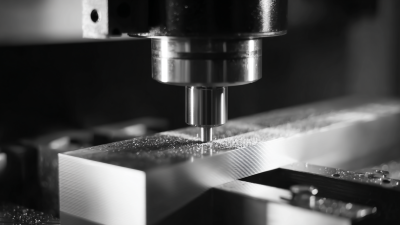

In the world of precision engineering solutions, the significance of brass machining cannot be overstated. Brass machining is not only integral to the manufacturing process but also enhances overall product performance. According to John Smith, a renowned expert in the field, "Brass machining offers unparalleled precision and versatility, making it a favored choice among engineers looking for reliable components." This sentiment resonates strongly in today’s competitive market, where the demand for high-quality, precise parts is at an all-time high.

The versatility of brass machined components offers numerous advantages, from corrosion resistance to ease of machining, setting it apart from other materials. Manufacturers are increasingly turning to brass machining to meet the evolving needs of various industries, including automotive, aerospace, and electronics. As we explore the top five benefits of brass machining, it will become clear why this process is essential for achieving excellence in precision engineering solutions. By leveraging the characteristics of brass, companies can ensure greater accuracy, durability, and cost-effectiveness in their products, thus solidifying brass machining's role at the forefront of innovation in engineering.

Advantages of Brass Machining in Precision Components Production

Brass machining offers numerous advantages for the production of precision components in engineering. One of the most significant benefits is its excellent machinability. Brass is known for its ease of cutting and shaping, which allows manufacturers to achieve high precision within tight tolerances. This characteristic is particularly valuable in the production of intricate parts, where detail and dimensional accuracy are paramount. The ability to quickly and efficiently create complex geometries reduces lead times and lowers production costs.

Another key advantage of brass machining is its superior corrosion resistance. Components made from brass can withstand harsh environments, making them ideal for applications in industries such as automotive and aerospace. This durability ensures that precision parts maintain their performance over time, leading to improved reliability and reduced maintenance needs. Furthermore, the aesthetic appeal of brass allows for components that not only function well but also look polished and professional, enhancing the overall quality of the finished product.

Enhanced Durability and Corrosion Resistance of Brass Parts

Brass machining plays a crucial role in precision engineering, particularly due to its enhanced durability and corrosion resistance. Brass, an alloy of copper and zinc, offers superior mechanical properties, making it a favored choice for components that must withstand harsh conditions. The intrinsic strength of brass ensures that parts maintain their shape and integrity, reducing the likelihood of wear and tear over time. This durability is essential in various applications, from automotive components to electronic fittings, where reliability is paramount.

Moreover, brass's exceptional corrosion resistance further elevates its appeal in precision engineering. Unlike many materials that degrade when exposed to moisture or aggressive environments, brass forms a protective patina when oxidized, which helps inhibit further corrosion. This characteristic allows brass components to perform effectively in both indoor and outdoor settings, ensuring longevity and reduced maintenance costs. The combination of these benefits positions brass machining as a valuable option for engineers seeking materials that can deliver high performance while enduring the challenges of their respective applications.

Cost-Effectiveness of Brass Machining for High-Volume Manufacturing

Brass machining stands out as a cost-effective solution for high-volume manufacturing, particularly in precision engineering. According to a report by the International Journal of Advanced Manufacturing Technology, brass components can lead to significant savings, with manufacturers often reporting reductions in production costs by up to 20%. This is largely due to brass's excellent machinability and the ability to run at higher feed rates, which accelerates production times without compromising quality.

When considering brass as a material for your machining needs, it's essential to evaluate the tooling and setup costs. One tip is to optimize your machining parameters, such as cutting speed and feed rate, to enhance efficiency. Implementing lean manufacturing principles can also reduce waste and improve overall resource allocation, further driving down costs.

Additionally, investing in advanced machining technologies, such as CNC machines tailored for brass, can yield high precision while minimizing operational expenses. Maintaining equipment regularly will ensure consistent performance and longevity, thereby maximizing your return on investment. By leveraging these strategies, manufacturers can harness the full cost-saving potential of brass machining in their precision engineering projects.

Improved Precision and Tolerances in Engineered Brass Solutions

Brass machining has become an integral part of precision engineering solutions, driven by its superior qualities that enhance precision and tolerances. According to a report by the Precision Metalforming Association (PMA), components made from brass can achieve tolerances as tight as ±0.002 inches, making them ideal for applications in industries like automotive, aerospace, and electronics. This precision is crucial in scenarios where small margins can significantly impact performance and safety, such as in connector fittings and valve components.

Furthermore, modern machining techniques, such as CNC (Computer Numerical Control) machining, have elevated the capabilities of brass manufacturing. A study from the International Journal of Advanced Manufacturing Technology highlighted that CNC technology can deliver up to 30% improved precision compared to traditional machining methods. This advancement allows for intricate designs while maintaining stringent tolerances, enabling engineers to produce complex brass components that meet the demanding specifications of contemporary engineering projects. As such, the benefits of enhanced precision and tighter tolerances solidify brass as a preferred material for precision-engineered components.

Top 5 Benefits of Brass Machining for Precision Engineering Solutions

| Benefit | Description | Impact on Engineering |

|---|---|---|

| High Precision Tolerances | Brass machining allows for tight tolerances, minimizing discrepancies in manufacturing. | Improves quality and performance in engineered components. |

| Excellent Corrosion Resistance | Brass is inherently resistant to corrosion, extending product lifespan. | Reduces maintenance costs and enhances reliability. |

| Versatility in Applications | Can be used in various fields including automotive, aerospace, and precision instruments. | Increases product adaptability and reduces barriers for innovation. |

| Ease of Machining | Brass is easy to machine, which leads to lower production costs and time. | Enhances efficiency and speeds up the manufacturing process. |

| Aesthetic Appeal | Brass has a distinct color and finish, adding visual value to products. | Attracts consumers and enhances brand perception. |

Versatility of Brass in Various Precision Engineering Applications

Brass has emerged as a pivotal material in precision engineering due to its superior mechanical properties and versatility across various applications. According to a market report by Research and Markets, the global brass machining market is projected to grow at a CAGR of 5.4% over the next five years, highlighting the increasing demand for brass components in sectors such as automotive, aerospace, and electronics. Its combination of strength, ductility, and corrosion resistance makes brass an ideal choice for manufacturing intricate parts that require precise tolerances and durability.

In addition to mechanical advantages, brass's excellent machinability further enhances its appeal in precision engineering. A study by the National Institute of Standards and Technology indicated that components made from brass exhibit superior wear resistance compared to those made of common steel alloys, which is critical in high-performance applications. With its low friction properties, brass minimizes wear and tear in moving parts, leading to longer lifespans and reduced maintenance costs. This versatility allows engineers to utilize brass in a wide range of products, from connectors and fittings to custom machined components tailored to specific industry needs.

Top 5 Benefits of Brass Machining for Precision Engineering Solutions

Related Posts

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

How to Choose the Best Precision CNC Machining Services for Your Projects

-

2025 Top 10 5 Axis CNC Machines Revolutionizing Precision Manufacturing

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes

-

Exploring High Precision Machining: Innovations Driving a $90 Billion Industry

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing