How to Choose the Right CNC Machine for Your Manufacturing Needs

Choosing the right CNC machine is a pivotal decision that can significantly impact your manufacturing operations. With a multitude of options available, understanding the specific needs of your production process is essential in making an informed choice. CNC machines, known for their precision and automation capabilities, are vital tools in various industries, from automotive to aerospace, providing high-quality outputs while minimizing waste and operational costs.

As the demand for efficiency and quality continues to rise, selecting the appropriate CNC machine tailored to your unique requirements is more important than ever. Factors such as material types, production volume, and desired complexity of parts bear considerable weight in your selection process. Additionally, it’s crucial to consider the machine’s capabilities, including its size, speed, and software compatibility, to ensure it aligns with your operational goals.

In this guide, we will explore the key considerations to keep in mind when choosing a CNC machine, helping you navigate the myriad of choices available in the market. By understanding these factors, you can enhance productivity, maintain high quality standards, and ultimately drive the success of your manufacturing endeavors.

Understanding Your Manufacturing Requirements for CNC Machines

Choosing the right CNC machine for your manufacturing needs involves a careful assessment of your specific requirements. Understanding factors such as material type, desired precision, and production volume is crucial. For instance, advanced CNC solutions now offer capabilities such as 2.5 to 5-axis machining, which can significantly enhance efficiency and flexibility in complex manufacturing environments. As the CNC market is projected to grow, particularly in Europe, with an anticipated increase from USD 8.2 billion in 2025 to USD 13.4 billion by 2035 within the woodworking sector, it is essential to select machines that align with market trends and technological advancements.

**Tips:** To optimize your machine selection, prioritize understanding what materials you will primarily work with and the tolerances needed for your projects. Additionally, evaluate your current and projected production volumes—this will influence whether a high-capacity or specialized CNC machine best suits your manufacturing line.

Understanding digital twins of machine tools can also guide your decision-making. These virtual replicas allow you to simulate and analyze machine performance under different conditions, ensuring that the chosen CNC machine can meet your operational demands without unnecessary risks. By leveraging real-time data analytics and machine learning, manufacturers can enhance their operations for better productivity and precision, contributing to smarter manufacturing practices.

Types of CNC Machines and Their Applications

When it comes to choosing the right CNC machine for manufacturing needs, understanding the variety of machines available can significantly impact operational efficiency and production quality. CNC machines can be categorized into several types, each tailored for specific applications. Common types include CNC milling machines, CNC lathes, CNC plasma cutters, and CNC routers. For instance, CNC milling machines are excellent for creating complex shapes, while CNC lathes are best suited for cylindrical parts. According to recent industry reports, the global CNC machine market is projected to grow substantially, reaching USD 195.59 billion by 2032, indicating an increasing reliance on these machines across various sectors.

**Tips:** When selecting a CNC machine, consider the materials you will be working with and the complexity of the parts to be produced. It's crucial to match the machine's capabilities with your manufacturing requirements. Additionally, evaluating the size and space requirements of your operational area can help streamline the integration of the new equipment into your workflow.

Another important aspect is the scalability of the machine. As reported, the market for CNC machines is anticipated to grow at a CAGR of 9.9% during the forecast period, emphasizing the need for machines that can adapt to evolving production needs. Investing in flexible CNC solutions can help ensure that your manufacturing processes remain competitive in a dynamic market.

Key Specifications to Consider When Choosing a CNC Machine

When selecting a CNC machine, it’s crucial to consider key specifications that align with your manufacturing needs. First, the machine's rigidity and stability are paramount, as these factors directly impact precision and surface finish. Look at the construction materials and design; a well-built machine can withstand vibrations and provide greater accuracy, especially during complex machining processes.

Another essential specification is the spindle speed and power. The spindle speed dictates how fast the machine can operate, affecting material removal rates based on the type of material being processed. A higher spindle speed may be beneficial for softer materials, while a powerful spindle is necessary for harder materials. Additionally, the feed rate and cutting tools compatibility play vital roles in determining the overall efficiency and capability of the CNC machine, making it essential to match these with your intended applications. By thoroughly evaluating these specifications, you can ensure that the CNC machine you choose optimizes your manufacturing workflow.

Evaluating Budget and Cost-Effectiveness of CNC Machines

When evaluating budget and cost-effectiveness of CNC machines, it’s crucial to consider both the initial investment and the long-term operational costs. The purchase price of a CNC machine can vary significantly based on its specifications, capabilities, and brand reputation. Thus, conducting thorough market research and comparing different options will help identify machines that fit within your financial constraints while meeting production requirements.

Furthermore, operational costs, such as maintenance, tooling, and energy consumption, must be factored into the overall budget. Some machines may have lower purchase prices but higher maintenance needs or operational inefficiencies, leading to increased long-term expenditures. It’s important to analyze the total cost of ownership by forecasting both the direct and indirect costs associated with running the machinery. Look for machines that offer durability and reliability, as these aspects can lead to savings over time through reduced downtime and maintenance requirements.

How to Choose the Right CNC Machine for Your Manufacturing Needs - Evaluating Budget and Cost-Effectiveness of CNC Machines

| CNC Machine Type | Initial Cost ($) | Operating Cost/Hour ($) | Maintenance Cost/Year ($) | Max Workpiece Size (mm) | Production Speed (mm/min) |

|---|---|---|---|---|---|

| CNC Mill | 30,000 | 15 | 1,200 | 1,000 | 500 |

| CNC Router | 25,000 | 10 | 800 | 2,500 | 600 |

| CNC Laser Cutter | 40,000 | 20 | 1,500 | 3,000 | 700 |

| CNC Plasma Cutter | 35,000 | 18 | 1,000 | 2,000 | 550 |

Maintenance and Support Considerations for CNC Machinery

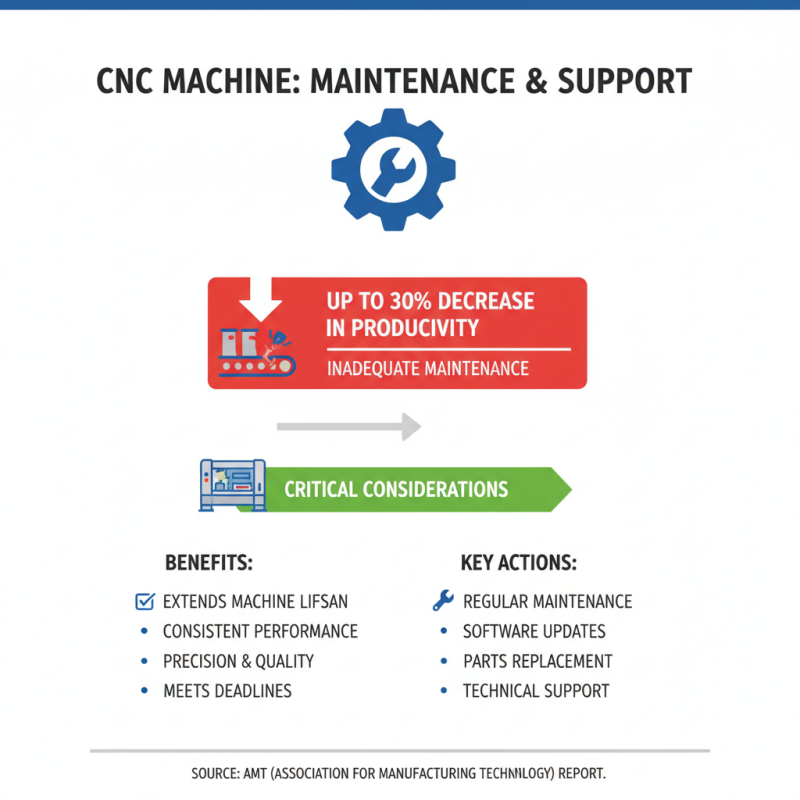

When selecting a CNC machine for your manufacturing operations, considerations for maintenance and support are critical. According to a report by the Association for Manufacturing Technology (AMT), manufacturers can experience up to a 30% decrease in productivity due to inadequate maintenance of CNC machines. Regular maintenance not only extends the lifespan of the machine but also ensures consistent performance and precision, which are vital for meeting production deadlines and maintaining quality standards.

Moreover, the availability of technical support and replacement parts plays a significant role in minimizing downtime. A survey conducted by the Machinery Research Institute showed that 62% of manufacturers prefer CNC machines from suppliers that offer comprehensive after-sales support, including training and technical assistance. This support can prove invaluable in troubleshooting issues swiftly, allowing companies to maintain operational efficiency and reduce costs associated with unplanned outages. Selecting a CNC machine with robust maintenance and support frameworks can therefore be a strategic move that directly impacts a manufacturer's bottom line.

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Best Precision CNC Machining Services for Your Project

-

Why Accurate CNC Machine Quotations Are Essential for Cost-Effective Manufacturing

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques