How to Choose the Right CNC Machine for Your Projects and Budget

Choosing the right CNC machine for your projects and budget can be a daunting task, especially with the myriad of options available in today’s market. As noted by renowned CNC industry expert John Smith, “Selecting the right CNC CNC machine is not just about the price; it’s about finding the perfect balance between functionality and your specific project needs.” This insight highlights the importance of understanding what features are essential for your applications while also being mindful of your financial constraints.

When embarking on this journey, it's critical to assess your project requirements and how they align with the capabilities of various CNC CNC machines. Factors such as material types, precision levels, and production volume play a significant role in determining the most suitable choice for your work. Additionally, budget considerations should not overshadow the importance of reliability and after-sales support, which can significantly impact the long-term success of your operations.

Ultimately, the decision-making process involves careful consideration of both immediate needs and future growth. By leveraging expert advice and doing thorough research, you can ensure that you select a CNC CNC machine that not only meets your current demands but also supports your ambition for expansion and innovation down the line.

Understanding CNC Machines: Types and Their Applications

CNC (Computer Numerical Control) machines have revolutionized the manufacturing and fabrication industries by providing precision, repeatability, and efficiency in the production of complex parts and products. Understanding the different types of CNC machines and their applications is crucial for selecting the right one for your projects, especially when working within a specific budget. Common types of CNC machines include CNC milling machines, CNC lathes, CNC plasma cutters, and CNC routers. Each type serves distinct purposes: for instance, CNC milling machines are ideal for creating intricate parts with high tolerances, while CNC routers are better suited for woodworking and softer materials.

According to a report from MarketsandMarkets, the global CNC machine market is expected to reach $117 billion by 2026, growing at a CAGR of 7.3% from 2021. This growth underscores the importance of choosing the appropriate CNC technology tailored to specific applications. For example, CNC plasma cutters are widely used in the metal fabrication industry due to their ability to cut through thick materials quickly, while CNC lathes accommodate both turning and drilling operations, making them versatile for producing cylindrical parts. As the demand for customized manufacturing solutions continues to rise, it becomes increasingly essential for businesses to understand the capabilities and limitations of each CNC machine type to optimize their production processes effectively.

How to Choose the Right CNC Machine for Your Projects and Budget - Understanding CNC Machines: Types and Their Applications

| Machine Type | Common Applications | Price Range (USD) | Best For |

|---|---|---|---|

| CNC Milling Machine | Metal and wood cutting, complex shapes | $10,000 - $200,000 | Precision machining |

| CNC Router | Woodworking, sign making | $3,000 - $50,000 | Large sheet materials |

| CNC Plasma Cutter | Metal fabrication, cutting steel and aluminum | $5,000 - $30,000 | Heavy materials |

| CNC Laser Cutter | Engraving, cutting wood, acrylic, and metal | $10,000 - $100,000 | Fine details |

| CNC 3D Printer | Prototyping, design, custom parts | $500 - $5,000 | Rapid prototyping |

Assessing Your Project Requirements and Specifications

When selecting the right CNC machine for your projects, it is essential to begin with a thorough assessment of your project requirements and specifications. Start by evaluating the materials you will be working with, whether they are wood, metal, plastic, or composite. Different machines have varying capabilities and limitations when it comes to material handling, so you need to choose a machine that is compatible with your chosen materials. Additionally, consider the thickness and dimensions of the materials to ensure that the CNC machine can accommodate your specific needs.

Next, reflect on the complexity and precision of the designs you plan to create. If your projects involve intricate details or tight tolerances, you will need a CNC machine with high accuracy and advanced features such as multi-axis capabilities. It’s also crucial to think about the scale of your operations—if you require high-speed production or large batch runs, investing in a more robust, industrial-grade machine might be justified. Conversely, for hobbyist projects or small-scale applications, a more affordable, smaller CNC machine may suffice. By closely analyzing your project specifications and requirements, you can make an informed decision that aligns with both your creative vision and budget constraints.

Determining Your Budget: Costs and Financing Options

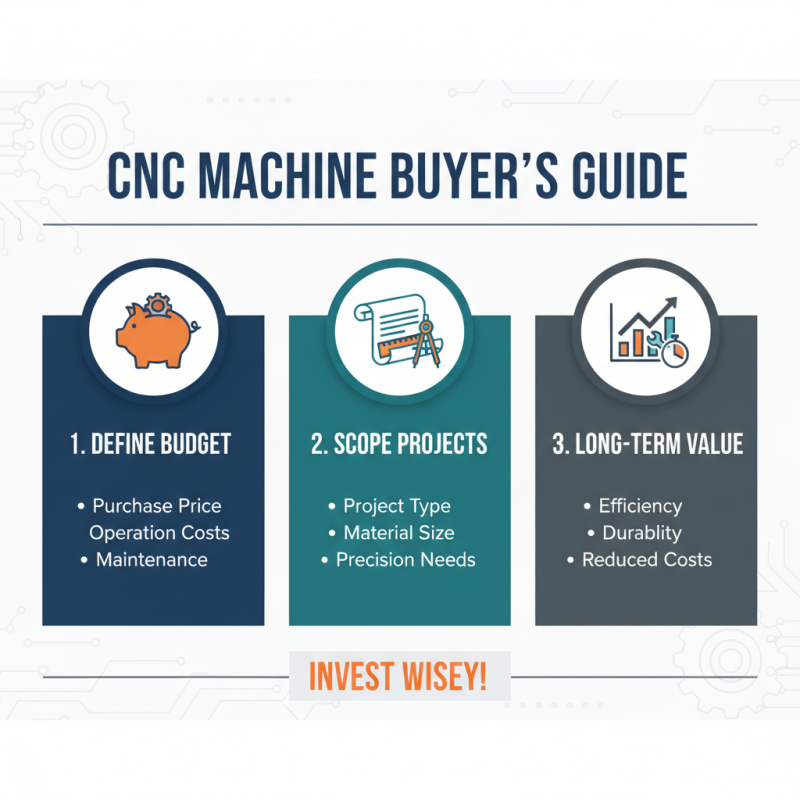

When choosing a CNC machine, determining your budget is a crucial initial step. The costs associated with CNC machinery can vary widely based on factors such as size, features, and capabilities. It’s essential to first define the scope of your projects, as this will help clarify what specifications you truly need. Additionally, consider not just the purchase price but also the operation and maintenance costs over time. A more expensive machine may be a better investment if it offers greater efficiency and durability, leading to reduced long-term costs.

Financing options can alleviate some of the financial pressure associated with acquiring a CNC machine. Many dealers offer payment plans or leasing options, which allow you to spread out the cost over time while still gaining access to the equipment you need. Furthermore, exploring local grants or business loans can provide additional support, especially for small businesses looking to expand their capabilities. Keep in mind that investing in the right machine is not just about the upfront cost, but rather the potential return on investment that efficient machinery can bring to your operations.

Evaluating CNC Machine Features and Capabilities

When selecting the right CNC machine for your projects and budget, evaluating the features and capabilities is essential. Start by identifying the specific materials you plan to work with, as different machines are tailored for wood, metal, or plastic. Consider the machine's spindle speed and power; higher RPMs allow for smoother cuts and the ability to handle tougher materials. Additionally, check the machine's maximum work area to ensure it can accommodate the size of your projects.

**Tips:** Always look for machines that offer a robust support system and community-based resources. This can significantly ease troubleshooting and learning processes, especially for beginners.

Another crucial feature to assess is the control interface. A user-friendly control software can save you time and reduce errors during setup and execution. If possible, opt for CNC machines that come with advanced capabilities such as built-in tool compensation and automatic calibration, as these can enhance precision and efficiency in the long run.

**Tips:** Don't hesitate to reach out to other users or forums to gather insights on machine performance and reliability. Real-world feedback can provide valuable information beyond technical specifications.

Comparison of CNC Machine Types Based on Key Features

Tips for Sourcing and Purchasing a CNC Machine

When sourcing and purchasing a CNC machine, it's essential to first identify your specific project requirements and budget constraints. Start by assessing the materials you will work with and the complexity of the designs you plan to create. This understanding will guide you towards the appropriate type of CNC machine—whether it’s a router, mill, or laser cutter. Additionally, consider factors such as the machine’s size, speed, accuracy, and compatibility with your existing software.

Once you have a clear idea of your needs, explore various sourcing options. Research local suppliers, online marketplaces, and auctions to compare prices and features. Don’t hesitate to reach out to manufacturers directly for quotes, as they can often provide insights on customization and additional services. Before finalizing your purchase, it’s prudent to verify the supplier's reputation through reviews and testimonials. Investing in a machine that comes with good after-sales support can also ensure a smoother operation and reduce downtime in your projects.

Related Posts

-

How to Choose the Right CNC Machine for Your Manufacturing Needs

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Best Precision CNC Machining Services for Your Project

-

Why Accurate CNC Machine Quotations Are Essential for Cost-Effective Manufacturing

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques