How to Choose CNC Parts Machining Services for Your Project?

Choosing the right CNC parts machining services is crucial for project success. The industry has seen a remarkable growth rate of around 7% annually. This rapid development highlights the increasing demand for precision-engineered components. According to a study by Market Research Future, the global CNC machining market is expected to reach $100 billion by 2025.

“Selecting the right partner is as important as the machine itself,” says John Harrison, a veteran in the CNC parts machining industry. His insights resonate with many engineers. They understand that collaboration with the right service provider can significantly impact the overall quality of the final product.

While many companies claim expertise, evaluating their capabilities is essential. Cheaper options may lead to subpar outcomes. Not every service provider focuses on the long-term relationship, a crucial aspect for ongoing projects. Therefore, assessing each potential partner’s experience and technology used is vital for ensuring reliability and precision in CNC parts machining.

Understanding the Basics of CNC Parts Machining Services

CNC parts machining is a crucial part of modern manufacturing. It can offer precision, efficiency, and versatility. In 2022, the global CNC machines market was valued at approximately $69 billion, proving its significance. Understanding CNC machining helps you select the right services for your project.

Key aspects include material selection and machining techniques. You’ll encounter options like aluminum and steel. Each has unique properties. Aluminum is lightweight and resistant to corrosion. Steel, on the other hand, provides strength and durability. This choice impacts your project’s performance and cost. It's important to know the intended use of your parts. Different applications may require diverse machining techniques.

Communication with service providers is vital. Discuss your project details and timeline. Some service providers may rush processes, potentially impacting quality. Industry reports indicate that 30% of projects suffer delays due to poor communication. Make sure to inquire about their quality control processes. This helps ensure the finished parts meet your specifications. Remember, not every service provider is created equal. Choose one that aligns with your specific needs.

Key Factors to Consider When Choosing CNC Machining Providers

Choosing CNC parts machining services can be daunting. It’s crucial to consider several key factors. One significant aspect is the provider's expertise. Look for companies that have experience in your specific industry. Their familiarity with similar projects can save time and resources.

Another important factor is the technology they use. Advanced CNC machines can enhance precision and efficiency. Ensure the provider employs the latest technologies that align with your project needs. Moreover, assess their quality control processes. Consistent quality checks can prevent costly errors in the final product.

Also, communication is vital. A responsive team can address any concerns or changes promptly. Consider their customer support reputation as well. If they struggle to communicate or meet deadlines, it may lead to frustrating delays. Reflect on previous customer feedback. It's essential to learn from past experiences, both theirs and yours, to avoid potential pitfalls.

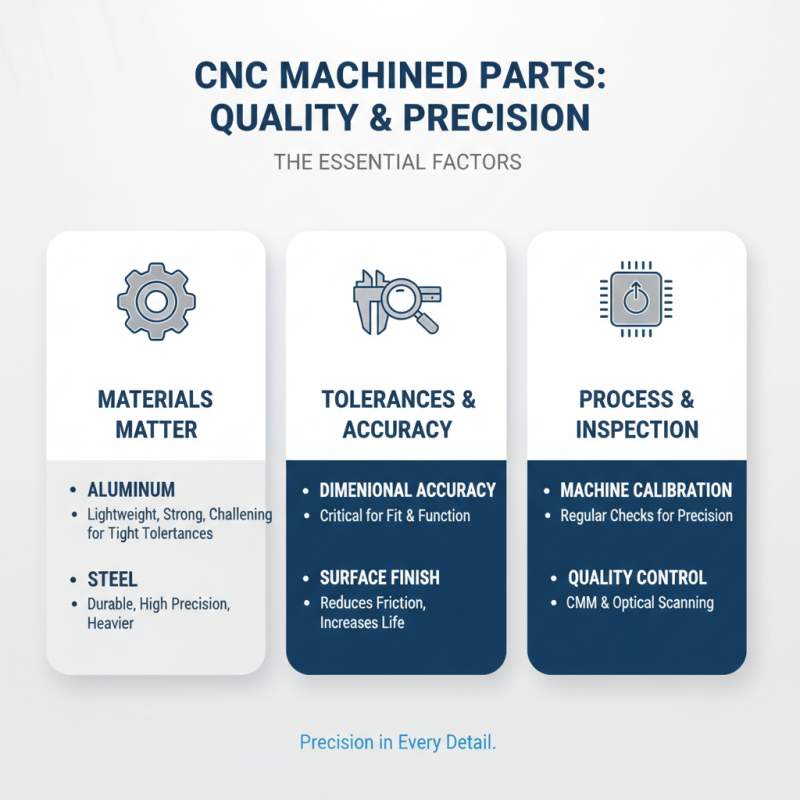

Evaluating the Quality and Precision of CNC Machined Parts

When evaluating the quality and precision of CNC machined parts, attention to detail is crucial. Start by considering the materials used. Different materials can affect the durability and accuracy of the final product. Aluminum, for example, is lightweight and strong, making it a popular choice. However, it can be more challenging to machine to high tolerances.

Next, check the machining techniques employed. A variety of methods exist, such as turning, milling, and grinding. Each has its advantages and limitations. Some providers may not invest in advanced technology, which can lead to inconsistencies. Pay attention to the equipment they use. Old machines may struggle to meet high precision standards.

Finally, review their previous work closely. Look for samples that showcase the quality of their CNC parts. Are there visible imperfections or inconsistencies? This can signal potential issues in their processes. While many services claim high precision, not all deliver. So, meticulous evaluation will help you ensure the best choice for your project.

Comparing Costs and Services of Different CNC Machining Companies

Choosing CNC parts machining services requires careful consideration of costs and services offered by various companies. It's essential to collect multiple quotes. This provides a clearer picture of market rates. Look beyond just the price. Evaluate the quality and reliability of each service provider. A lower cost may mean compromises on quality.

Comparing services is equally important. Not all companies provide the same level of expertise. Some may excel in rapid prototyping, while others might focus on mass production. Request samples to gauge their craftsmanship. It's also wise to check for customer reviews. Sometimes, great prices can hide a lack of support. Consider how responsive they are to inquiries.

Reflect on your project's specific needs. Some companies might have limited capabilities that can hinder production timelines. Be cautious of hidden fees too. These can inflate costs unexpectedly. Transparency is crucial in this decision-making process. Engaging with companies about your concerns may reveal their willingness to adapt to your requirements.

Comparison of CNC Parts Machining Services

Assessing Turnaround Times and Delivery Options for CNC Parts

When selecting CNC parts machining services, turnaround time is crucial. A fast turnaround can significantly impact your project timeline. Evaluate how long each service provider usually takes from order placement to delivery. Some might promise quick services, but those guarantees should be verified.

Consider various delivery options offered by different providers. You might find expedited shipping rates appealing, but they can escalate costs. On the other hand, standard shipping may save money but could delay your project. If your timeline is tight, striking a balance between speed and cost is essential.

Sometimes, a machining provider may not communicate delivery updates effectively. This lack of communication can become a source of frustration. Ensure to clarify how they will keep you informed about progress and any potential delays. Choosing a service with clear communication policies can help mitigate issues and improve your overall experience.

Related Posts

-

What is CNC Manufacturing and How Does it Impact Modern Production

-

Ultimate Tips for Efficient CNC Parts Machining Every Engineer Should Know

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

How to Choose the Best Precision CNC Machining Services for Your Project