10 Essential Tips for Mastering CNC Precision Machining Techniques

In the world of manufacturing, CNC precision machining stands as a pivotal technique that transforms raw materials into intricately designed components with remarkable accuracy. Experts in the field emphasize the importance of mastering these techniques to ensure consistent quality and efficiency. As John Smith, a renowned authority in CNC precision machining, aptly states, “Mastering CNC precision is not just about the machines; it's about understanding the materials and the processes that shape them.”

In this context, mastering CNC precision requires a blend of technical know-how and practical application, making it essential for professionals to continually refine their skills. This guide outlines ten essential tips that will empower machinists to elevate their craftsmanship and embrace the intricacies of CNC technology. From selecting the right tools to understanding the intricacies of tool path programming, these insights will help both novices and seasoned veterans achieve superior precision in their projects.

As advancements in CNC technology continue to evolve, staying informed and adapting to these changes becomes crucial. By implementing the strategies covered in this article, you will not only enhance your proficiency in CNC precision machining but also position yourself as a leader in a competitive industry.

Understanding the Fundamentals of CNC Machining for Precision Work

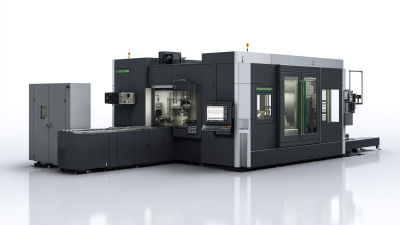

CNC machining plays a crucial role in the manufacturing industry, providing the precision needed for intricate parts and components. Understanding the fundamentals is essential for achieving high-quality results. At the heart of effective CNC machining are post processors, which are pivotal in converting CAD designs into machine-readable instructions. Knowing how to utilize them in your CNC software can significantly enhance your workflow and precision.

One of the key tips for mastering CNC precision machining techniques is to familiarize yourself with the specific post processor associated with your machine. This will ensure that the G-code generated is compatible, minimizing errors and setup time. Additionally, always double-check your tool paths and parameters before starting a job. This small step can prevent costly mistakes and ensure that your final product adheres to the desired specifications.

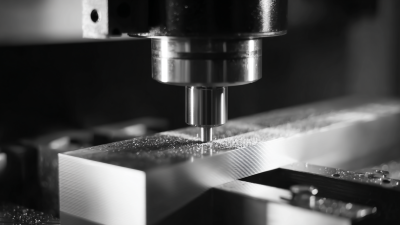

Another important tip is to keep your tools sharp and well-maintained. Dull tools can lead to imprecise cuts and poor finishes, impacting the overall quality of your work. Regular maintenance and calibration of your CNC machine will also help maintain its performance, allowing you to achieve the level of precision required for your projects. By integrating these practices into your machining routine, you can elevate your skills and produce exceptional results.

10 Essential Tips for Mastering CNC Precision Machining Techniques

Choosing the Right Tools and Materials for Optimal CNC Performance

When it comes to mastering CNC precision machining, selecting the right tools and materials is crucial for achieving optimal performance. High-quality tools can enhance accuracy, reduce wear, and improve cutting efficiency. According to a recent industry report, using advanced tooling systems can increase machining productivity by up to 30%. Therefore, investing in the correct tools tailored to your specific projects can lead to substantial gains in both time and cost efficiency.

In addition to tooling, choosing the proper materials is equally important. The compatibility of the material with your machining capabilities can significantly impact the final product's quality. For instance, using materials recommended for CNC machining can yield superior finishes and minimize post-processing. An essential tip is to match your tool selections with the properties of the materials you intend to work with, as this can greatly enhance the overall machining process.

Furthermore, utilizing design software that aligns with your manufacturing needs can streamline the process. This software offers intelligent solutions by merely inputting your requirements, eliminating the need for in-depth design knowledge. By leveraging such tools, users can efficiently optimize their machining strategies and focus on the fundamental aspects of production, ensuring a smooth workflow and significant improvements in CNC performance.

Techniques to Ensure Accurate Measurements in CNC Projects

In the realm of CNC precision machining, accurate measurements are paramount to achieving high-quality results. Implementing advanced imaging systems, similar to those used in fusion-based metal additive manufacturing, can significantly enhance measurement accuracy. These technologies allow for real-time monitoring and adjustments, reducing the margin of error during the machining process. For instance, studies have shown that incorporating sophisticated imaging techniques can drastically improve the precision of manufactured components, which is essential in industries where tolerances can be as tight as 0.001 inches.

Furthermore, the benefits of precision engineering extend to various sectors, including construction and manufacturing. As reported, the adoption of precision machining practices can lead to notable cost savings, particularly in industries plagued by material degradation, such as oil refining. The estimated annual costs associated with corrosion in these sectors can reach around $8 billion, emphasizing the necessity for precise engineering solutions that enhance component lifespan. By focusing on precision in machining techniques, industries can optimize performance and ensure reliability in their production processes.

10 Essential Tips for Mastering CNC Precision Machining Techniques

| Tip | Description | Benefits |

|---|---|---|

| Use Quality Tools | Invest in high-quality cutting tools to improve precision. | Enhances longevity and reduces errors in machining. |

| Calibrate Machines Regularly | Ensure your CNC machine is consistently calibrated. | Improves accuracy and reliability of measurements. |

| Optimize Tool Paths | Plan efficient paths to reduce machine movement. | Increases speed and reduces the risk of errors. |

| Use Proper Feed Rates | Adjust feed rates according to material and tooling. | Prevents tool wear and improves surface finish. |

| Implement Coolant Strategies | Use coolant effectively to manage heat during machining. | Reduces thermal distortion and prolongs tool life. |

| Ensure Workpiece Stability | Secure your workpiece properly to avoid movement. | Improves dimensional accuracy during machining. |

| Regular Maintenance of Equipment | Perform routine checks and maintenance on machinery. | Ensures consistent performance and accuracy. |

| Use Probe and Measurement Tools | Incorporate probing systems for in-process measurements. | Allows for real-time adjustments and minimizes errors. |

| Understand Material Properties | Study the materials you work with to optimize settings. | Enhances machining strategies and reduces waste. |

| Keep Learning and Adapting | Stay updated with new techniques and technologies. | Continued education leads to better results and efficiency. |

Implementing Proper Maintenance to Enhance CNC Machine Longevity

Proper maintenance of CNC machines is crucial for enhancing their longevity and performance in today's rapidly evolving manufacturing landscape. With the increasing integration of digitalization and automation in manufacturing processes, effective maintenance strategies have become even more essential. By implementing predictive maintenance techniques, manufacturers can leverage data analytics and machine learning models to monitor the condition of their CNC equipment continuously. This proactive approach minimizes unplanned downtime and costly repairs, ensuring that machines operate at peak efficiency.

Incorporating advanced technologies such as IoT allows for real-time data collection from machines, facilitating a better understanding of wear patterns and operational anomalies. This not only helps in tailoring maintenance schedules based on actual machine performance but also enhances overall productivity. By taking advantage of these innovative methodologies, businesses can ensure their CNC machines are not only maintained effectively but are also positioned to meet the demands of precision machining in an increasingly competitive market.

Utilizing Advanced Software for Enhanced CNC Machining Precision

The integration of advanced software in CNC machining is transforming the landscape of precision manufacturing. With the global computer-aided manufacturing (CAM) market projected to reach approximately USD 7.60 billion by 2033, the importance of cutting-edge software solutions can’t be overstated. These tools not only enhance productivity but also improve accuracy, enabling manufacturers to achieve intricate designs with minimal waste.

To master CNC precision machining techniques, one must utilize the latest advancements in software. For instance, leveraging GPU-accelerated simulation can significantly enhance CNC toolpath generation, allowing for smoother operations and better edge finishing. This emphasizes the need for continuous education and adaptation to new technologies within the industry.

Additionally, integrating robotics software can lead to substantial improvements in both accuracy and scalability. Collaborations that combine machining research with sophisticated software capabilities are paving the way for next-level manufacturing. By embracing these innovations, manufacturers can stay competitive in an increasingly demanding market, where precision and efficiency are paramount.

Related Posts

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

Exploring High Precision Machining: Innovations Driving a $90 Billion Industry

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes