Exploring High Precision Machining: Innovations Driving a $90 Billion Industry

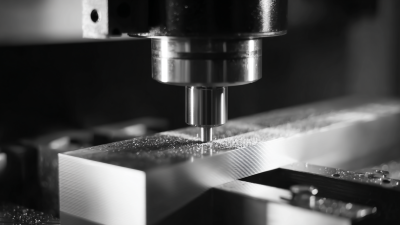

In the rapidly evolving landscape of manufacturing, high precision machining stands out as a key driver of innovation and efficiency, shaping a formidable $90 billion industry. As the demand for meticulous accuracy increases across various sectors, experts emphasize the vital role that cutting-edge technologies and methodologies play in enhancing production capabilities. Dr. Emily Chen, a renowned expert in high precision machining, remarked, "The future of manufacturing hinges on our ability to harness precision and efficiency; it's not just about meeting standards, but exceeding them."

As we explore the intricacies of this dynamic field, it becomes evident that advancements in materials, tooling, and automation are propelling high precision machining into new realms of possibility. Industry leaders are investing significantly in research and development to optimize processes, reduce waste, and deliver products with unparalleled accuracy. This quest for precision not only drives economic growth but also supports the evolution of sophisticated applications in aerospace, automotive, and medical devices, highlighting how high precision machining is integral to technological advancement and competitive advantage in today's market.

Ultimately, understanding the innovations in high precision machining is crucial for stakeholders aiming to navigate the complexities of this thriving industry. Whether through implementing state-of-the-art machinery or refining operational strategies, the potential for growth and improvement is extensive, urging us to delve deeper into what this pivotal sector has to offer.

Innovative Techniques Transforming the High Precision Machining Landscape

The landscape of high precision machining is rapidly evolving, driven by innovative techniques and the adoption of digital manufacturing technologies. As businesses place a greater emphasis on efficiency and productivity, the global CNC machine market is projected to witness significant growth, with an estimated market value of $77 billion anticipated by 2024, reflecting a compound annual growth rate (CAGR) of 5.5%. This upward trend is indicative of the technological advancements being integrated into various manufacturing processes, which are redefining productivity benchmarks across multiple sectors.

In Europe, the CNC machine market presents a promising outlook, projected to expand as industries increasingly leverage advanced machining technologies. The focus on innovation within the engineering and construction sectors has become critical; firms are encouraged to adopt new technological solutions in order to capitalize on emerging market opportunities in 2026. Moreover, the integration of cutting-edge tools in 3D reconstruction and landscape restoration showcases how the blend of deep learning and innovative methodologies can enhance existing capabilities and drive industry transformation. As these innovations continue to flourish, they are set to reshape the future of high precision machining.

The Role of Data Analytics in Enhancing Machining Precision

Data analytics plays a pivotal role in enhancing precision within the

high precision machining industry, a sector poised for significant growth. By harnessing the power of

data, manufacturers can monitor and optimize machining processes in real-time, leading to improved accuracy and reduced waste.

Predictive analytics, for instance, enables operators to anticipate potential equipment failures or deviations, allowing for timely interventions that minimize downtime and maintain high standards of quality.

Furthermore, advanced data analytics tools facilitate the analysis of operational trends, helping organizations to refine their machining strategies.

Machine learning algorithms can identify patterns in production data, supporting decision-making processes that enhance precision.

This data-driven approach not only leads to more efficient resource allocation but also fosters innovation in tool design and manufacturing techniques. As the industry evolves,

leveraging data analytics will be crucial in meeting the increasing demand for higher precision and efficiency in machining processes.

Emerging Materials Reshaping High Precision Machining Applications

The high precision machining industry, valued at approximately $90 billion, is undergoing a transformative phase driven by the advent of emerging materials. These materials, including advanced ceramics, composite materials, and high-performance alloys, are redefining the capabilities and applications of machining processes. According to a recent study by Research and Markets, the demand for such innovative materials is projected to grow at a CAGR of 6.5% over the next five years, reflecting the increasing need for lightweight and durable components in industries like aerospace, automotive, and medical devices.

One notable innovation is the development of ceramic matrix composites (CMCs), which offer exceptional strength-to-weight ratios and thermal stability. These characteristics make CMCs ideal for high-temperature applications, particularly in the aerospace sector where components must withstand extreme conditions. Additionally, the rise of additive manufacturing techniques is allowing for the production of complex geometries that were previously unattainable, further enhancing the functionality of precision machined parts. As the industry embraces these advanced materials, companies are not only improving operational efficiency but also pushing the boundaries of what is possible in high precision machining.

High Precision Machining Innovations by Material Type

Sustainability Initiatives in the High Precision Machining Industry

The high precision machining industry, valued at approximately $90 billion, is undergoing significant transformation driven by sustainability initiatives. As environmental concerns rise, companies are increasingly adopting eco-friendly practices. The implementation of energy-efficient machinery, waste reduction protocols, and the use of biodegradable materials are becoming commonplace. These innovations not only help in reducing the carbon footprint but also enhance operational efficiency.

Incorporating sustainable engineering plastics, such as biodegradable polyamide and recycled polycarbonate, is another critical aspect of this shift. These materials not only meet performance requirements but also align with the industry's commitment to responsible manufacturing. By utilizing advanced materials that are less harmful to the environment and can be reused or recycled, the high precision machining sector is pioneering a move toward a more sustainable future. This commitment not only fulfills corporate social responsibilities but also drives consumer preference, ultimately reshaping industry dynamics.

Exploring High Precision Machining: Innovations Driving a $90 Billion Industry - Sustainability Initiatives in the High Precision Machining Industry

| Innovation Area | Description | Impact on Sustainability | Estimated Market Growth |

|---|---|---|---|

| Adaptive Machining | Technology that self-adjusts tools for changing material conditions. | Reduces waste and energy consumption. | 15% CAGR over the next 5 years. |

| Additive Manufacturing | 3D printing technologies for complex geometries. | Minimizes material use and promotes recycling of materials. | 20% CAGR by 2028. |

| Intelligent Automation | AI-driven systems for optimizing machining processes. | Enhances efficiency, reducing resource consumption. | 10% CAGR projected through 2030. |

| Sustainable Materials | Use of biodegradable and recyclable materials in machining. | Lower environmental footprint and enhances lifecycle of products. | 12% CAGR estimated for sustainable materials by 2025. |

| Energy-efficient Machines | Advanced machining equipment designed to consume less energy. | Significantly reduces overall factory energy usage. | 8% CAGR expected, driven by energy regulations. |

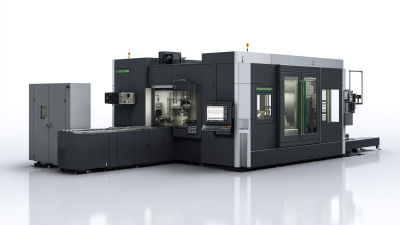

Future Trends: AI and Automation in Precision Machining Processes

The precision machining industry, projected to reach a staggering $90 billion by 2032, is undergoing transformative changes driven largely by artificial intelligence (AI) and automation. As these technologies become more integrated into manufacturing processes, they are reshaping operations, enhancing efficiency, and ensuring greater accuracy in production. The growing incorporation of AI is enabling real-time data analysis and predictive maintenance, which significantly reduces downtime and operational costs.

Forecasts indicate that the global AI market will soar from $294.16 billion in 2025 to an impressive $1.77162 trillion by 2032, showcasing a remarkable compound annual growth rate (CAGR) of 29.2%. This rapid expansion underscores the increasing reliance on smart technologies to streamline precision machining. Innovations such as machine learning algorithms and automated systems are not only improving product quality but also facilitating quicker turnaround times, thus providing businesses with a competitive edge in the evolving marketplace. As the industry embraces these advancements, the future of precision machining will likely be characterized by increased automation, enhanced productivity, and unparalleled precision.

Related Posts

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing