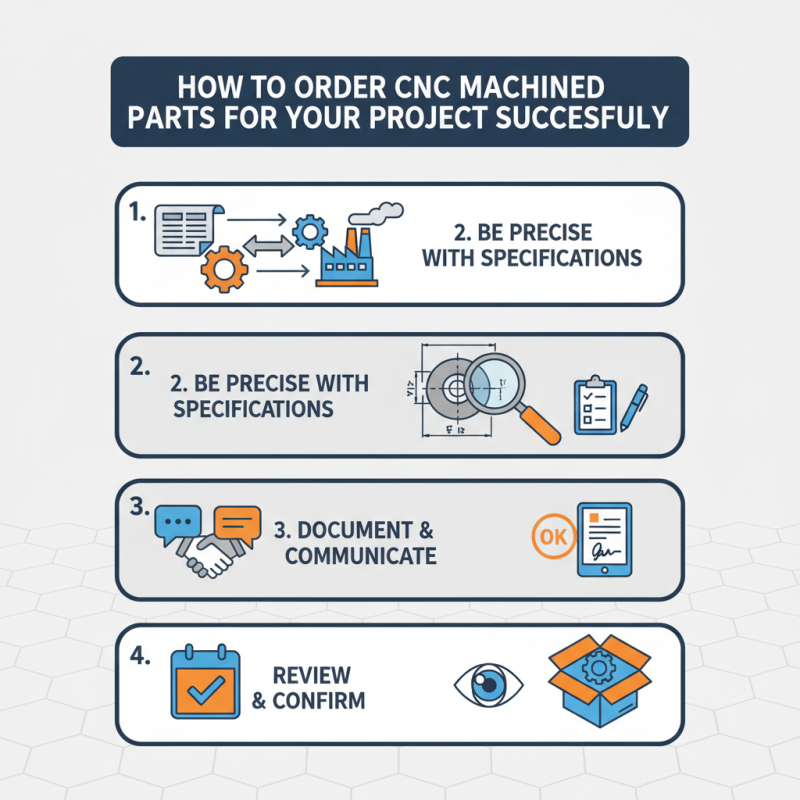

How to Order CNC Machined Parts for Your Project Successfully?

When it comes to ordering CNC machined parts, understanding the entire process is crucial. John Smith, an expert in precision machining, once remarked, “Clarity in your specifications saves time and reduces costs.” This insight underscores the importance of being precise when you order CNC machined parts for your project. Clear specifications set the stage for successful outcomes.

Many professionals overlook the significance of detailed drawings and material requirements. Without careful attention, mistakes can happen, leading to delays and increased expenses. For instance, submitting vague specifications can result in receiving parts that do not meet your expectations. It’s vital to double-check every detail.

Relying on verbal communication alone can lead to misunderstandings. Document everything and ask for confirmations. Even seasoned engineers sometimes find themselves regretting a lack of thoroughness. In one case, a client received parts with incorrect tolerances, simply due to inadequate communication. Reflecting on these experiences can improve your future orders. Prior preparation can make all the difference, so take time to get it right.

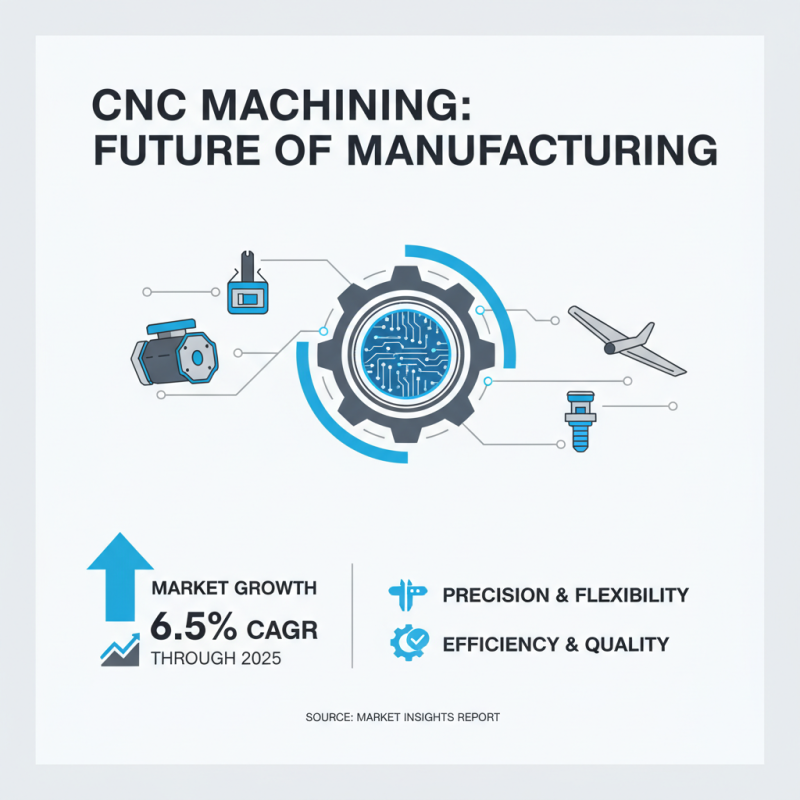

Understanding CNC Machining and Its Benefits for Your Project

CNC machining is a pivotal method in modern manufacturing. It provides precision and flexibility for various projects. According to a recent report by Market Insights, the CNC machining market is projected to grow at a CAGR of 6.5% through 2025. This growth reflects how industries value CNC’s efficiency and quality.

The technology allows for intricate designs and complex geometries. CNC machines operate on CAD files, translating digital designs into tangible parts. However, a common oversight is neglecting thorough pre-production planning. Rushed decisions can lead to design flaws or material wastage. It's crucial to evaluate the entire production process. Proper planning minimizes errors, optimizing both time and costs.

Materials also play a critical role in CNC machining. Selecting the right material influences the part’s functionality and durability. Metals like aluminum and titanium are popular choices due to their strength-to-weight ratio. However, using budget materials can compromise quality. It's essential to strike a balance between cost and performance, which requires careful analysis. This reflection ensures reliability and project success.

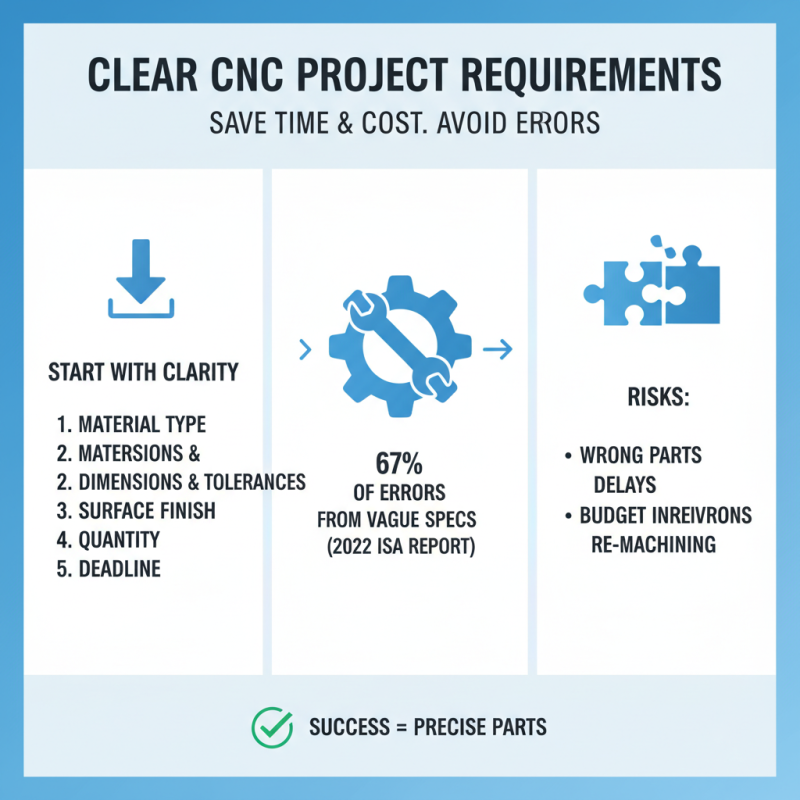

Defining Your Project Requirements for CNC Machined Parts

Defining your project requirements is crucial when ordering CNC machined parts. A clear understanding can save time and costs. According to a 2022 report by the International Society of Automation, nearly 67% of CNC machining errors stem from vague specifications. Ambiguities can lead to parts that do not fit or function as intended.

When detailing requirements, focus on dimensions, tolerances, and materials. The tighter the tolerances, the more precise the machining must be. A study by Machining Cloud noted that 58% of manufacturers reported challenges due to insufficient tolerance specifications. Include drawings and models; visual aids can bridge gaps in communication. Yet, only 33% of project managers provide adequate visuals, leading to misinterpretations.

Mind the complexities of your project. Unique or innovative designs may require specialized knowledge. Research indicates that 45% of CNC shops hesitate to take on complex orders due to uncertain project parameters. This caution can lead to delays and additional costs. Defining robust requirements early on improves collaboration and outcomes. It helps manufacturers understand your vision and expectations.

Selecting a Reliable CNC Machining Service Provider

Choosing a reliable CNC machining service provider is crucial for your project’s success. Quality and precision matter. Start by examining the provider’s portfolio. Look for past projects similar to yours. It’s essential to assess their capabilities and technology. Not all companies have the same machines or expertise.

Tips: Ask about their quality control processes. This can reveal how they maintain standards. A good provider will be transparent about their steps. Don't hesitate to request samples. They can give you a clear picture of what to expect.

Communication is key. Discuss your specifications and needs in detail. A responsive provider will ask questions. They’ll likely clarify any ambiguous points. Red flags include long response times or vague answers. You want a partner who is invested in your success.

Tips: Always check reviews and testimonials. Feedback from previous clients helps you gauge reliability. If a service consistently receives complaints, take note. Look for patterns in service delivery. A past record is often an indicator of future performance.

Delivery Time of CNC Machined Parts from Different Providers

This chart illustrates the delivery time for CNC machined parts provided by various service providers. It highlights the range of delivery times from 3 to 7 days, which is critical for planning and project management.

Placing Your Order: Key Information and Considerations

When placing an order for CNC machined parts, clarity is crucial. Start by detailing your specifications. Include dimensions, materials, and finishes. The more precise you are, the easier it is for the manufacturer to understand your needs. Often, vague descriptions lead to misunderstandings. This can result in wasted time and resources.

Next, consider the production timeline. Estimate how long each phase should take, but be open to adjustments. Delays can happen, so communicate openly with the supplier. It’s better to set realistic expectations than to rush the process. Additionally, understand the importance of prototyping. Sometimes, creating a prototype can reveal design flaws early on. This step can save you significant costs later.

Remember to double-check all details before sending your order. Simple mistakes can have serious consequences. A wrong measurement can lead to unusable parts. It’s essential to review everything, even if you think you’ve got it right. It might feel tedious, but thoroughness pays off in the end.

Evaluating Quality and Adjustments After Receiving Your Parts

When you receive your CNC machined parts, the evaluation process is crucial. Start by visually inspecting each piece. Look for surface imperfections, burrs, or any unexpected defects. Use calipers and gauges to measure critical dimensions. This step is vital to ensure that the parts meet your specified tolerances. Keep in mind that even well-manufactured parts can have slight variances.

Once the initial inspection is complete, consider the functional aspects. Test how the parts fit within your assembly. Do they interact as intended? It's not uncommon to find that minor adjustments are necessary. Document any issues you encounter, noting which aspects need refinement. This feedback is valuable for improving future orders. Reflecting on the results can lead to better communication with your manufacturer. Adjustments may include tweaking designs or changing machining processes. Embrace this iterative phase to enhance your project's success.

How to Order CNC Machined Parts for Your Project Successfully?

| Dimension | Measurement (mm) | Material | Surface Finish | Quantity | Lead Time (days) |

|---|---|---|---|---|---|

| Length | 100 | Aluminum 6061 | Anodized | 50 | 10 |

| Width | 50 | Steel A36 | Painted | 100 | 15 |

| Height | 25 | Stainless Steel 304 | Polished | 200 | 12 |

| Thickness | 5 | Carbon Steel | Galvanized | 75 | 20 |

Related Posts

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

Top 10 Benefits of CNC Aluminum Machining for Your Next Project

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

What is Steel Fabrication? Understanding Processes, Benefits, and Applications

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

2026 How to Select the Best CNC Steel Machining Techniques?