What is Prototype Manufacturing and Its Importance in Product Development?

Prototype manufacturing is a crucial phase in product development. It allows companies to create tangible representations of concepts. According to a report by the Product Development and Management Association, over 70% of organizations rely on prototypes to test ideas before launch.

This method not only boosts creativity but also reduces risks. A well-crafted prototype can unveil issues early on. For instance, engineering challenges become apparent, enabling teams to pivot swiftly. However, many companies still face hurdles in effectively using prototypes.

Data indicates that companies with effective prototype manufacturing see a 50% reduction in time to market. Yet, not every prototype serves its purpose. Some designs fail to capture user needs, highlighting the importance of user feedback. This iterative process is vital. It demands continuous refinement and challenges teams to enhance their products genuinely.

Definition and Overview of Prototype Manufacturing

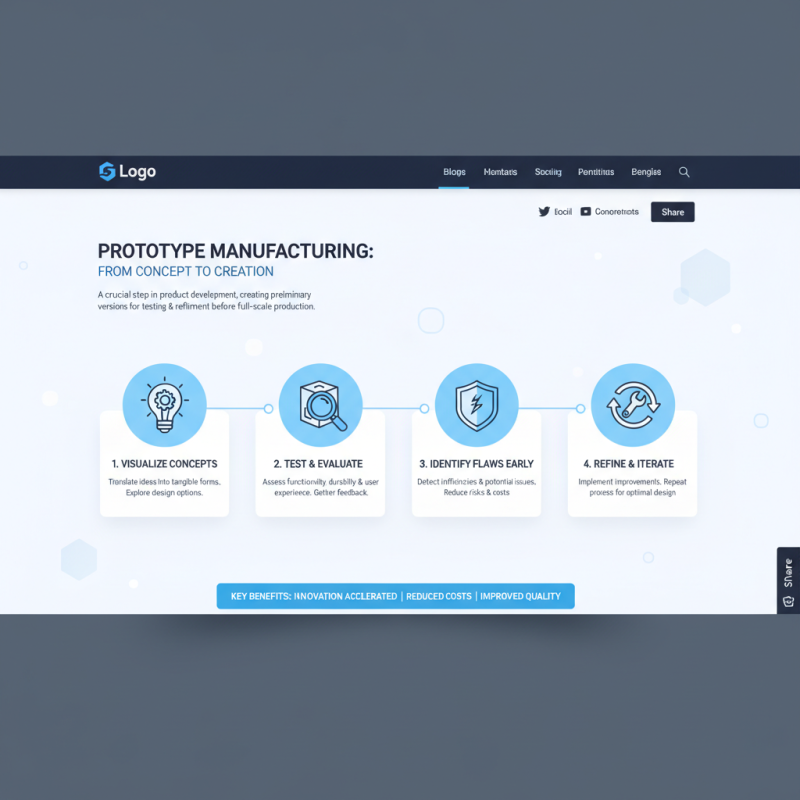

Prototype manufacturing is a crucial step in product development. It involves creating a preliminary version of a product to test different aspects before full-scale production begins. This process allows designers and engineers to visualize concepts. It also helps identify any flaws or inefficiencies early on.

Creating a prototype can lead to unexpected challenges. Materials may not perform as expected. Design features could pose manufacturing difficulties. Iterative testing reveals what works and what doesn’t. This feedback is invaluable for refining ideas. A prototype can range from a simple mock-up to a fully functional model. Each version brings new insights and possibilities.

Effective prototype manufacturing fosters innovation. It encourages collaboration among team members. Different perspectives can highlight potential issues. However, it can be time-consuming and costly. Sometimes, resources are stretched thin. Yet, the benefits of a well-thought-out prototype often outweigh these drawbacks. Clear communication and adaptability are key in this phase.

Key Processes Involved in Prototype Manufacturing

Prototype manufacturing is a crucial step in product development. It allows designers and engineers to create tangible versions of their ideas. This process helps in visualizing the product and testing its functionality. Various methods are involved, each serving a unique purpose.

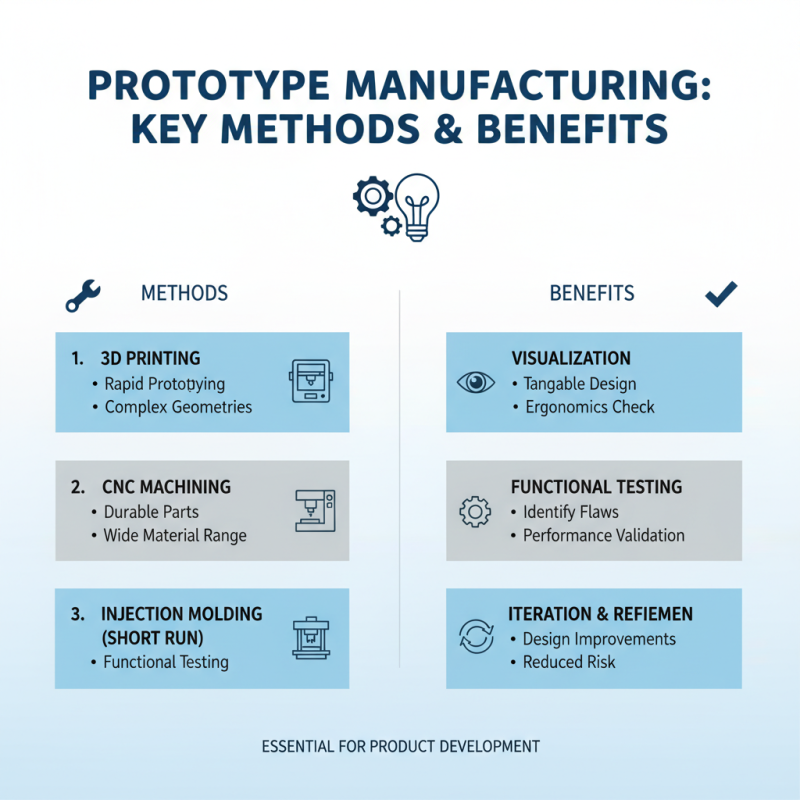

One key process is 3D printing. It enables rapid prototyping and allows for intricate designs. However, the quality of materials used can affect results. Another important method is CNC machining. It is precise but may require longer lead times.

Additionally, assembly prototyping helps evaluate product ergonomics. It's essential but often overlooked. Teams may encounter setbacks in the design phase, leading to wasted materials and time. The challenge lies in finding a balance between speed and quality. A prototype should not only look good but also perform as expected.

Types of Prototypes Used in Product Development

Prototyping is a critical step in product development. Different types of prototypes serve distinct purposes. In fact, about 73% of organizations use prototypes to enhance their product design process, according to recent industry reports.

Low-fidelity prototypes are often the first step. They can be paper sketches or basic digital mockups. These prototypes allow teams to explore ideas quickly. They help visualize concepts without spending too much time on details. However, these early versions can miss key functionalities and user interactions. Feedback at this stage is crucial to avoid future complications.

High-fidelity prototypes offer more realism. They include interactive features and detailed designs. According to a study, 68% of product teams prefer high-fidelity prototypes for user testing. These versions simulate the end product closely. Yet, they can be time-consuming to create. Teams often spend too much time refining details that may change later. Balancing detail and speed is a continuous challenge. It's important to remember that every prototype, regardless of fidelity, should facilitate learning and validation.

| Prototype Type | Description | Importance in Development | Common Uses |

|---|---|---|---|

| Low-Fidelity Prototype | Simple representations using paper, sketches, or basic digital formats. | Allows early feedback on concepts and ideas before detailed development. | Brainstorming sessions, initial testing of ideas. |

| High-Fidelity Prototype | Detailed and interactive prototypes resembling the final product. | Provides accurate user testing and feedback on functionality and aesthetics. | User testing, presentations to stakeholders. |

| Functional Prototype | A working model that demonstrates features or functionality. | Helps identify technical challenges and validate design decisions. | Engineering tests, demonstrating functionality to investors. |

| Vertical Prototype | Focuses on a specific feature or function of the product. | Allows for in-depth analysis of particular components before full-scale production. | Testing individual functionalities, feature-focused evaluations. |

| Horizontal Prototype | Demonstrates an overall look and feel without functional depth. | Used for visual and ergonomic assessments on design. | Design visualizations, early stakeholder approvals. |

Benefits of Prototype Manufacturing in Design Iteration

Prototype manufacturing plays a crucial role in the product development process. It allows designers to visualize ideas in a tangible form. This step is essential for testing concepts before large-scale production begins. One clear benefit is the ability to identify flaws early. When a prototype is created, designers can spot issues with functionality and design. This minimizes expensive revisions later on.

Incorporating feedback during design iterations is vital. Prototypes enable teams to gather insights from stakeholders. For example, they can show how a product looks and feels. Visual and physical feedback helps in refining the design. Teams can ask specific questions: Does it fit comfortably? Is the function clear? These queries deepen understanding of user needs.

Tip: Always encourage open feedback during prototype testing. It fosters creativity and improves results.

Prototyping also allows for experimentation. Designers often have to pivot their ideas. A prototype might reveal that an initial concept isn’t as effective as envisioned. This can be frustrating but is part of the growth process. Embracing these challenges can lead to innovation.

Tip: Document every iteration. Keeping track of changes can inform future projects.

Challenges and Solutions in the Prototype Development Process

Prototype development serves as a crucial step in transforming ideas into tangible products. However, the process is fraught with challenges. Designers often face tight deadlines, limited budgets, and a lack of resources. Many prototypes fail during initial testing, which can be disheartening. This setback leads to a realization: not all ideas are feasible. It’s essential to learn from these mistakes.

Communication gaps can also hinder progress. Designers and engineers may not fully understand each other’s needs. This often results in prototypes that miss the mark. Ensuring clear dialogue can mitigate these issues. Establishing regular check-ins facilitates better collaboration. Moreover, using rapid prototyping techniques can help streamline the process. However, even these methods come with their own set of challenges. Mistakes in material selection or measurement errors can lead to flawed designs.

Embracing iterative testing is another important solution. Gathering feedback early can guide improvements. Yet, it requires patience and flexibility. Sometimes, the path to a successful prototype is not a straight line. It’s crucial to remain adaptable and willing to pivot when necessary. This mindset fosters innovation, even amidst frustration. Acknowledging flaws and learning from them ultimately drives better product development.

Related Posts

-

Top 10 Benefits of Prototype Manufacturing for Your Business Success

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

-

What is Steel Fabrication? Understanding Processes, Benefits, and Applications

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

2026 How to Select the Best CNC Steel Machining Techniques?