Top Steel Machining Techniques You Need to Know for Precision Engineering

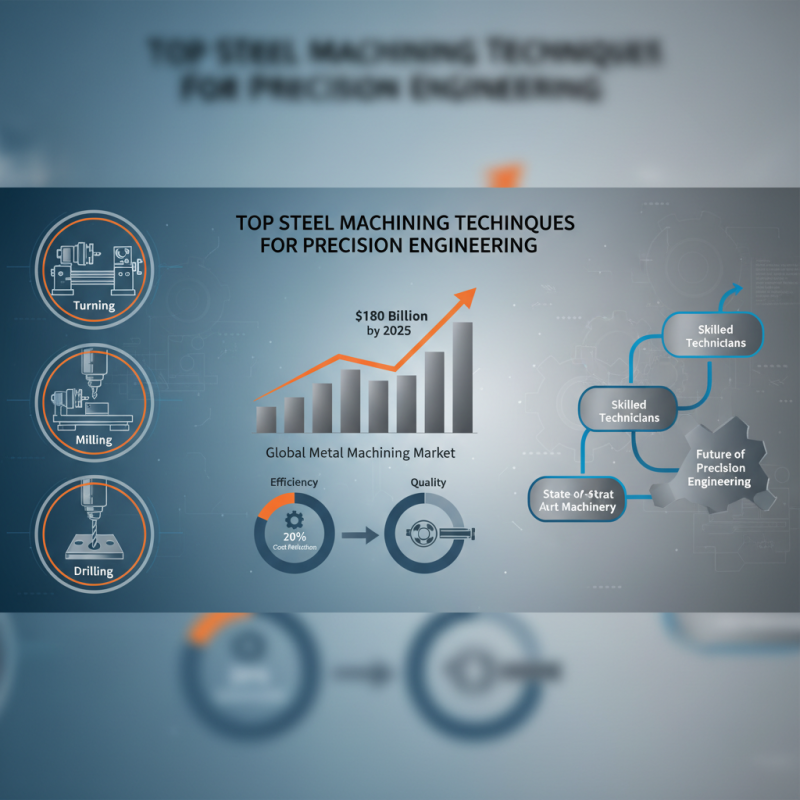

In the realm of precision engineering, steel machining has emerged as a critical process that underpins a vast array of industries, from aerospace to automotive. According to a report by the International Federation of Robotics, the global metal machining market is projected to reach USD 180 billion by 2025, driven by advancements in technology and increasing demand for high-quality steel components. Steel machining techniques, including turning, milling, and drilling, not only enhance the efficiency of manufacturing processes but also ensure that products meet stringent tolerances and specifications.

The significance of mastering steel machining techniques cannot be overstated, as it plays a vital role in optimizing production cycles and minimizing waste. A study published by the Manufacturing Institute highlights that effective machining practices can lead to a reduction in production costs by up to 20%, demonstrating the economic benefits of investing in skilled technicians and state-of-the-art machinery. As industries continue to evolve, understanding the latest trends and techniques in steel machining will position engineers and manufacturers at the forefront of innovation, ultimately driving the future of precision engineering.

Understanding the Fundamentals of Steel Machining in Precision Engineering

Precision engineering relies heavily on efficient and accurate steel machining techniques. Understanding the fundamentals of steel machining is crucial for achieving the high tolerances required in various applications. The process begins with selecting the right tools and parameters, which directly influence the surface finish and dimensional accuracy of the machined component. Techniques such as turning, milling, drilling, and grinding are foundational methods that engineers should master to create precise components for the industry.

When engaging in steel machining, it's essential to consider factors like cutting speed, feed rate, and tool material. Proper calibration of these variables can significantly enhance productivity and extend tool life.

**Tip:** Always conduct tests on scrap pieces before machining the final components. This practice allows you to fine-tune settings, ensuring optimal conditions and reducing waste.

Another critical aspect is the choice of cutting fluids, which not only cool the cutting tool but also improve the overall finish of the machined steel. Employing the right lubrication can minimize friction and prevent overheating, leading to better accuracy and longer tool longevity.

**Tip:** Regularly evaluate the cutting fluids for contamination, as this can affect the quality of your machining results. Proper maintenance can enhance performance and lower costs in the long run.

Top Steel Machining Techniques for Precision Engineering

This chart illustrates the efficiency of various steel machining techniques used in precision engineering, measured in hours required for each technique. Understanding these values helps in optimizing manufacturing processes and improving productivity.

Key Steel Machining Techniques: Milling, Turning, and Grinding Explained

Precision engineering relies heavily on various machining techniques to achieve the highest quality outcomes. Among these, milling, turning, and grinding stand out as essential methods in steel machining. Each technique has its unique processes and applications that cater to specific requirements in engineering projects.

Milling involves the use of rotary cutters to remove material from a workpiece. It is particularly effective for producing complex shapes and contours. When milling steel, using the right feed rate and cutting speed is vital to prevent overheating and ensure a clean finish.

Turning, on the other hand, is designed for cylindrical objects. This method rotates the workpiece while a cutting tool shapes the exterior or interior to desired specifications. To enhance precision during turning, ensure that the tool is sharp and properly aligned with the workpiece to avoid vibrations that could lead to inaccuracies.

Grinding is a finishing process that removes small amounts of material to achieve a smooth and accurate surface. It is indispensable for achieving tight tolerances in steel parts. To optimize grinding efficiency, maintain the right coolant flow to facilitate better heat dissipation and prolong the life of grinding wheels.

Tips: Always inspect your tools before commencing machining operations; dull or damaged tools can compromise accuracy and finish quality. Regular maintenance of machines is also crucial to ensure optimal performance and longevity.

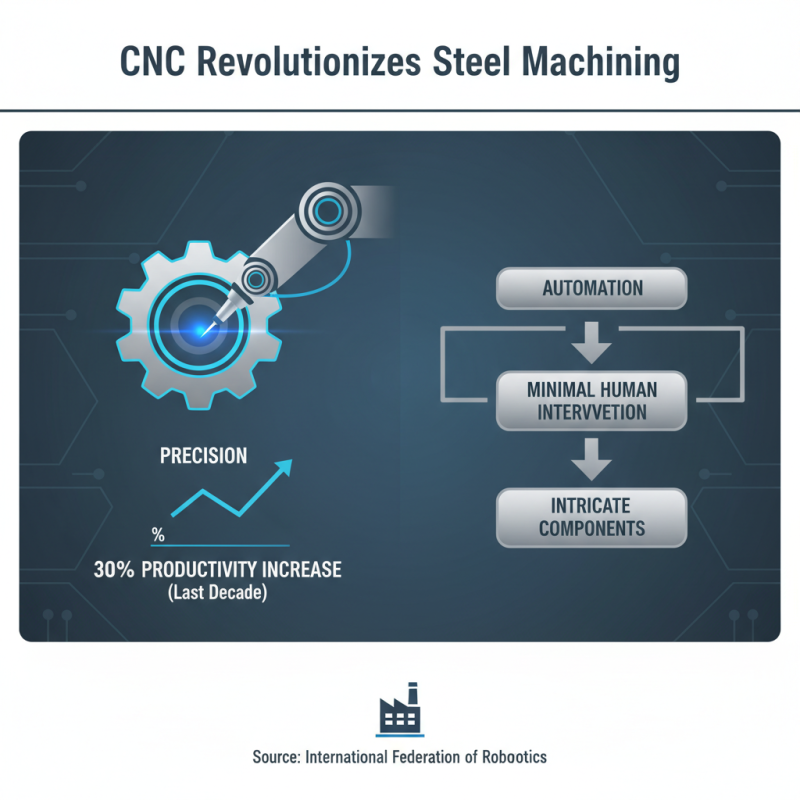

The Role of CNC Technology in Modern Steel Machining Processes

CNC (Computer Numerical Control) technology has revolutionized the steel machining sector, enabling a level of precision and efficiency that was previously unattainable. According to a report by the International Federation of Robotics, the use of CNC machines has increased the productivity of machining operations by approximately 30% over the last decade. This significant improvement is driven largely by the automation capabilities of CNC technology, which allows manufacturers to produce intricate components with minimal human intervention.

In modern steel machining processes, CNC systems employ advanced algorithms and software to execute complex machining tasks with high accuracy. This is vitally important in precision engineering, where tolerances of just a few micrometers can determine the functionality and performance of steel components in applications such as aerospace, automotive, and medical devices. Additionally, a study from the National Institute of Standards and Technology highlights that the incorporation of CNC technology reduces production cycle times by up to 25%, thereby improving overall operational efficiency. As industries continue to demand higher precision and lower production costs, the integration of CNC technology into steel machining processes will remain a critical factor for competitive advantage.

Choosing the Right Cutting Tools for Steel Machining Efficiency

When it comes to steel machining, the choice of cutting tools is paramount to achieving both efficiency and precision. Selecting the right tools not only influences the quality of the finished product but also impacts the speed and cost-effectiveness of the machining process. High-speed steel, carbide, and ceramic are among the most commonly used materials for cutting tools, each offering distinct advantages depending on the specific requirements of the operation. For instance, carbide tools are well-suited for high-volume production due to their durability and ability to withstand heat, while high-speed steel tools may be favored for their flexibility and ease of sharpening.

Moreover, the geometry of cutting tools plays a crucial role in enhancing machining performance. Factors such as the rake angle, clearance angle, and the number of flutes can significantly affect the cutting action and surface finish. Tools designed with optimized geometries allow for smoother chip removal and reduced cutting forces, which in turn promotes longevity and precision in machining steel. Additionally, advancements in coating technologies provide extra benefits by reducing friction and wear, further enhancing tool life and efficiency. Properly matching these tool characteristics with the specific steel type and machining conditions can lead to marked improvements in overall productivity and part quality.

Best Practices for Quality Control in Steel Machining Operations

In the realm of steel machining, maintaining stringent quality control standards is vital for ensuring precision engineering. Effective quality control practices begin with the implementation of standardized operating procedures (SOPs) that outline every aspect of the machining process. By clearly defining each step, from raw material inspection to final product verification, manufacturers can establish benchmarks for quality. Additionally, regular training sessions for operators can enhance their understanding of these procedures and help them identify potential issues early in the machining process.

Another best practice for quality control involves the use of advanced measurement and monitoring tools throughout the machining operations. Techniques such as in-process measurement, where tools monitor dimensions and tolerances during production, can prevent deviations from specifications. Moreover, adopting statistical process control (SPC) methods can assist in analyzing production data to detect trends and preemptively address variances. This data-driven approach not only enhances the reliability of the machining process but also fosters a culture of continuous improvement, ultimately resulting in superior quality products.

Top Steel Machining Techniques You Need to Know for Precision Engineering - Best Practices for Quality Control in Steel Machining Operations

| Machining Technique | Description | Quality Control Method | Key Benefits |

|---|---|---|---|

| CNC Machining | Computer Numerical Control machining for high precision and repeatability. | Dimensional Inspection using CMM | High accuracy, reduced human error, flexible production. |

| Laser Cutting | Using focused laser beams to cut or engrave materials. | Visual and dimensional checks | Clean edges, high precision, minimal waste. |

| Milling | Rotating multi-toothed cutter to remove material from a workpiece. | Tool wear monitoring | Versatility, ability to produce complex shapes. |

| Turning | Machining process for creating cylindrical parts by rotating the workpiece. | Surface finish measurement | High efficiency, good for mass production. |

| Grinding | A finishing process using an abrasive wheel to achieve a high surface quality. | Hardness testing | Precision finishing, improved surface properties. |

Related Posts

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

Top 5 Benefits of Brass Machining for Precision Engineering Solutions

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Right CNC Machine for Your Manufacturing Needs