Top 10 Precision Machining Techniques for Enhanced Manufacturing Efficiency

In the ever-evolving landscape of manufacturing, precision machining has emerged as a cornerstone technique that drives efficiency and accuracy in production processes. As companies strive to maximize productivity while maintaining the highest standards of quality, understanding the various precision machining techniques is essential for staying competitive. Dr. Emily Carter, a leading expert in the precision machining industry, aptly states, "Precision machining is not just about creating parts; it's about crafting excellence that impacts the entire supply chain." This insight underscores the significance of adopting effective machining methods to enhance operational efficiency.

With technology rapidly advancing, precision machining techniques continue to play a vital role in the optimization of manufacturing processes. From CNC milling to advanced lathing methods, each technique offers unique benefits that can streamline production and reduce waste. As we delve into the top ten precision machining techniques, it becomes evident how these innovations not only improve the quality of manufactured goods but also contribute to lower costs and faster turnaround times. In this article, we will explore these techniques in depth, providing insights into how they can foster enhanced manufacturing efficiency for businesses today.

Top 10 Precision Machining Techniques for Enhanced Manufacturing Efficiency

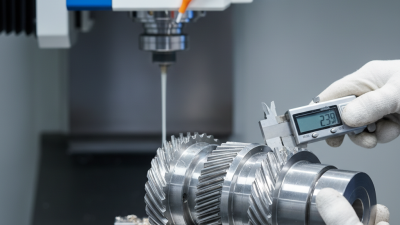

Precision machining is essential for enhancing manufacturing efficiency, as it allows for the creation of high-quality components with tight tolerances. Utilizing advanced techniques can significantly reduce waste, improve production speed, and increase the overall accuracy of the parts being manufactured. Techniques such as CNC machining, electrical discharge machining (EDM), and laser cutting play a crucial role in achieving these goals. By incorporating automation and digitally controlled processes, manufacturers can streamline their operations, leading to consistent and repeatable results.

When implementing precision machining techniques, it's vital to optimize tool selection and setup. Tip: Always choose the right tool for the material being machined. This not only prolongs tool life but also enhances performance. Additionally, maintaining proper machine calibration is crucial for ensuring that tools operate within specified tolerances. Regular checks can prevent costly errors and rework, thereby improving overall productivity.

Another key aspect is the integration of modern technologies such as 3D printing and advanced software for simulation. These innovations facilitate design testing and reduce lead times significantly. Tip: Utilize simulation software to identify potential issues before actual production begins. This proactive approach can save time and resources while allowing for adjustments to be made early in the process. By embracing these precision machining techniques, manufacturers can ensure they remain competitive while maintaining high standards of quality and efficiency.

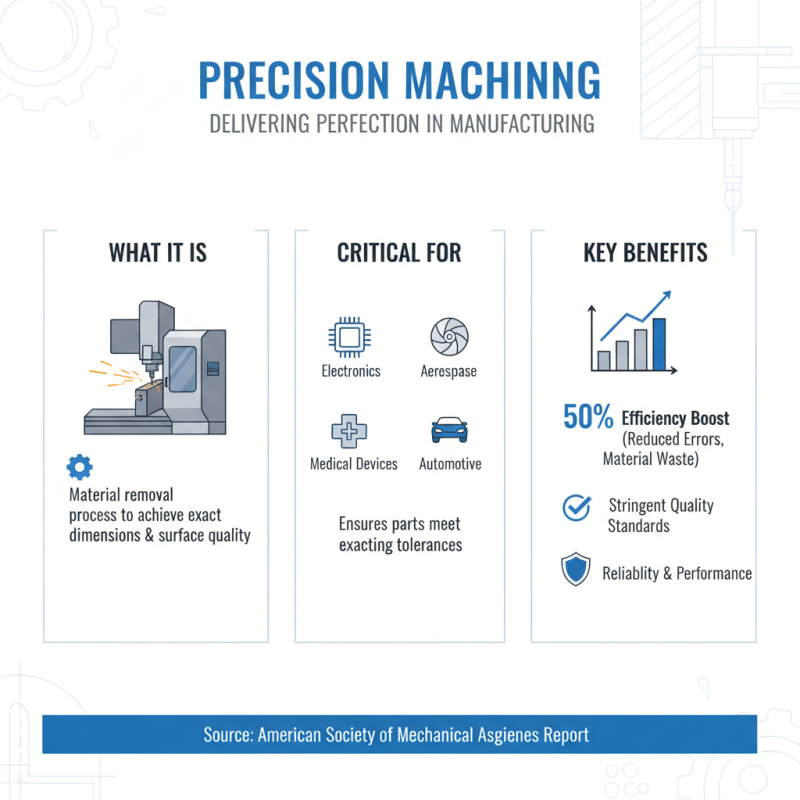

Understanding Precision Machining: Definition and Importance in Manufacturing

Precision machining is a critical process in modern manufacturing, ensuring parts are created with exacting tolerances to meet the demands of various industries. Defined as the process of removing material from a workpiece to achieve desired dimensions and surface quality, precision machining plays a pivotal role in delivering components that meet stringent quality standards. According to a report by the American Society of Mechanical Engineers, precision machining contributes to a 50% increase in manufacturing efficiency by reducing errors and material waste.

The significance of precision machining cannot be overstated, particularly in sectors like aerospace, automotive, and medical device manufacturing, where the reliability of components is paramount. For example, a report from the Precision Machined Products Association highlights that companies adopting advanced machining technologies experience a 30% reduction in production time. These techniques not only improve product quality but also enhance overall operational efficiency, thereby addressing the complex challenges faced by manufacturers today.

Tips: To optimize your machining processes, consider investing in CNC (Computer Numerical Control) technologies that provide consistent precision and can seamlessly handle complex geometries. Additionally, regular maintenance of machinery can prevent downtimes, ensuring that production schedules are met without compromising on quality. Emphasizing staff training in precision machining techniques can also yield significant benefits, fostering an environment of innovation and continuous improvement.

Key Metrics of Manufacturing Efficiency in Precision Machining Processes

Measuring manufacturing efficiency in precision machining is essential for optimizing production processes and ensuring high-quality outputs. Key metrics such as cycle time, setup time, and overall equipment effectiveness (OEE) provide valuable insights into how effectively resources are utilized. Cycle time measures the total time required to produce a part, including machining time and any idle time. Reducing cycle time not only enhances throughput but also minimizes operational costs, making it a vital focus for manufacturers.

Another critical metric is setup time, which refers to the time taken to prepare machines for production runs. Minimizing setup time through efficient planning and automation can significantly improve manufacturing efficiency by allowing for quicker transitions between different tasks or products. Additionally, OEE combines the effectiveness of machine performance, availability, and quality of output into a single metric, serving as a comprehensive indicator of production health. By analyzing these key metrics, manufacturers can identify bottlenecks and streamline processes, ultimately leading to enhanced performance and competitiveness in the precision machining industry.

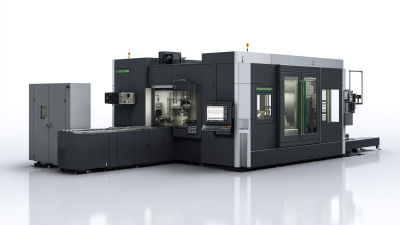

Technique 1: CNC Machining - Revolutionizing Precision Manufacturing Standards

CNC machining has emerged as a game-changer in the realm of precision manufacturing, offering unmatched accuracy and efficiency. According to a report by industry analysts, CNC machines can achieve tolerances as tight as ±0.005 mm, making them a preferred choice for manufacturers seeking high-quality results in their production processes. This level of precision is critical in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to catastrophic failures or costly rework.

The integration of CNC technology into manufacturing processes has not only enhanced precision but also streamlined operations. In a study conducted by the Precision Machining Association, it was found that manufacturers utilizing CNC machinery reported a reduction in production time by up to 30%. This efficiency gain allows companies to respond more rapidly to market demands while maintaining stringent quality standards. Moreover, the automation capabilities of CNC machines reduce the need for manual oversight, thereby lowering labor costs and minimizing human error—factors that are increasingly vital for competitive edge in today's fast-paced manufacturing landscape.

Technique 2: EDM (Electrical Discharge Machining) - Enhancing Precision and Detail

Electrical Discharge Machining (EDM) is a cutting-edge technique that utilizes electrical discharges to remove material from a workpiece, allowing for exceptional precision and detail in manufacturing. This method is particularly effective for hard materials that are difficult to machine using traditional techniques. As opposed to mechanical cutting, EDM works by employing thermal energy to erode unwanted material, creating intricate shapes that would otherwise be unattainable. This capability makes EDM invaluable in industries such as aerospace, medical device manufacturing, and mold making, where high tolerance levels and complex geometries are critical.

One of the standout features of EDM is its ability to produce complex parts with minimal stress to the workpiece, reducing the risk of deformation. Unlike conventional machining, where cutting tools exert mechanical forces, EDM operates through a series of rapid electrical discharges, resulting in a much gentler process. This precision translates to superior surface finishes and allows for the creation of features like sharp internal corners and fine details. Consequently, manufacturers can achieve higher product quality and lower tolerance levels, ultimately leading to enhanced overall efficiency in their operations. With the growing demand for precision engineering, EDM stands out as a critical technique in pushing the boundaries of manufacturing capabilities.

Conclusion

Precision machining plays a crucial role in enhancing manufacturing efficiency by ensuring high-quality production standards. This article delves into the top ten precision machining techniques that significantly improve operational productivity. Key metrics of manufacturing efficiency such as cycle time, waste reduction, and quality control are essential in evaluating these processes.

Among the featured techniques, CNC machining stands out for revolutionizing precision manufacturing through automation and versatility, while EDM (Electrical Discharge Machining) is lauded for its ability to achieve remarkable precision and detail in complex components. Additionally, surface grinding is highlighted for producing superior surface finishes, which are vital for the functionality and aesthetics of parts. Together, these techniques underscore the importance of precision machining in modern manufacturing settings, showcasing how they enhance both efficiency and product quality.

Related Posts

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

How to Choose the Best Precision CNC Machining Services for Your Projects

-

How to Achieve Superior Precision Milling Techniques for Your Projects

-

Top 10 Benefits of CNC Aluminum Machining for Your Next Project

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques