Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, precision CNC machining parts have emerged as a pivotal component driving innovation and efficiency across various industries. According to a report by Research and Markets, the global CNC machining market is projected to reach $100.1 billion by 2025, with precision machining at the forefront due to its ability to produce high-quality, complex components quickly and accurately.

This technological advancement enables manufacturers to meet the rising demand for customized products, enhance production speed, and reduce waste, positioning precision CNC machining as a key player in achieving competitiveness and sustainability. As businesses increasingly recognize the importance of precision in their manufacturing processes, the advantages offered by CNC machined parts become essential for fostering innovation and driving economic growth in the sector.

The Role of Precision CNC Machining in Advancing Manufacturing Techniques

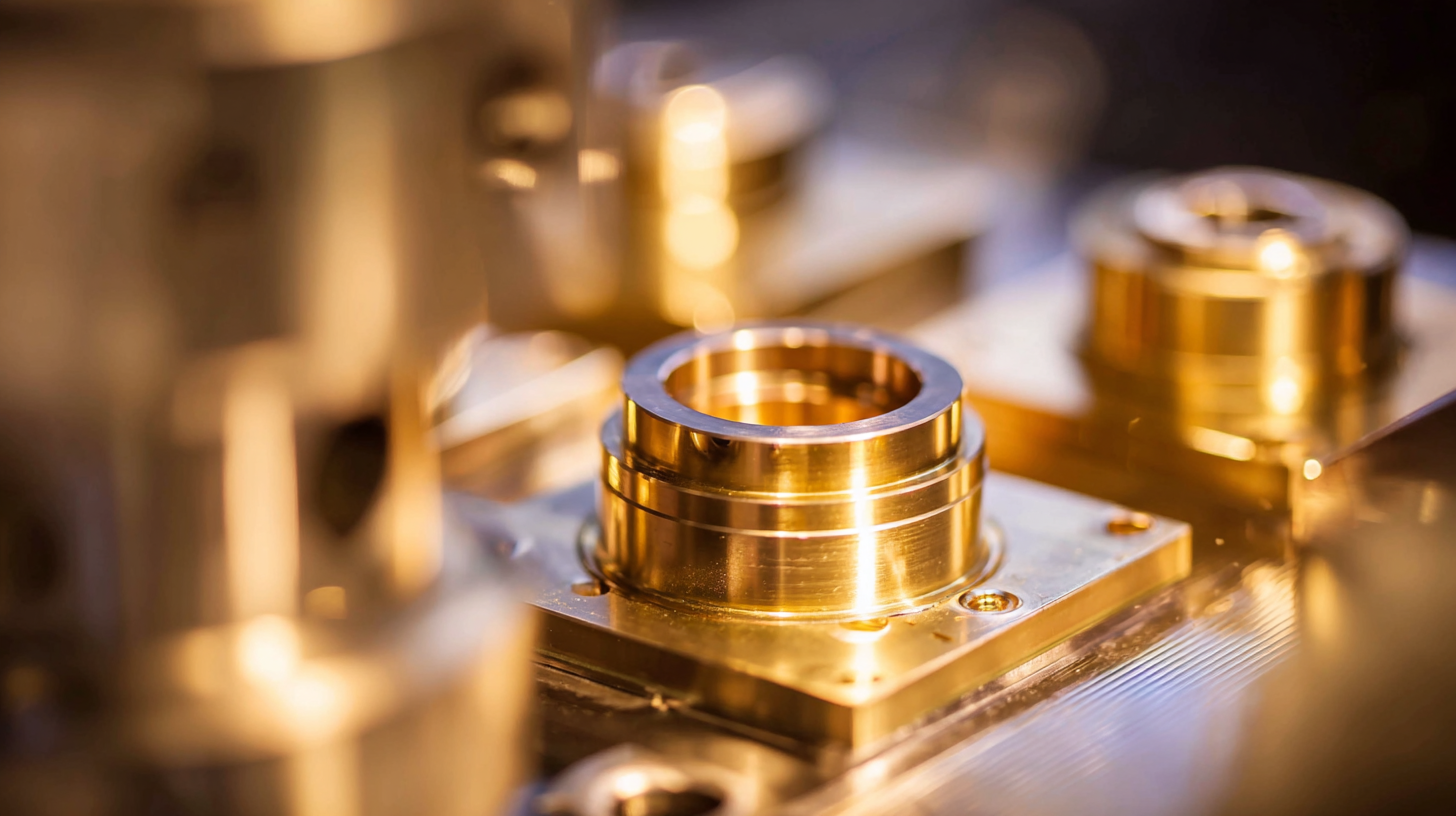

The role of precision CNC machining in advancing manufacturing techniques cannot be overstated. As industries strive to keep pace with evolving market demands, the integration of CNC machining has enabled manufacturers to achieve unparalleled accuracy in their production processes. By utilizing computer numerical control, companies can produce intricate parts with tight tolerances, ensuring that each component meets stringent specifications. This technological shift not only enhances product quality but also significantly reduces waste and production time.

Moreover, the arrival of digital manufacturing technologies has further elevated the capabilities of CNC machining. With the incorporation of advanced software and automation, manufacturers can now streamline their workflows, optimizing the entire production cycle from design to finished product. This evolution has not only led to increased productivity across various sectors but has also opened up new avenues for innovation. As companies embrace these modern techniques, they are better equipped to respond to changing consumer preferences and deliver tailored solutions that drive market growth.

Unlocking Innovation: The Impact of Precision CNC Machining on Manufacturing Techniques

Benefits of Precision CNC Machining for Custom Parts Production

Precision CNC machining has transformed custom parts production, delivering a range of benefits that modern manufacturers cannot afford to overlook. According to a 2021 report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2028, showcasing the growing reliance on this technology across various industries. One of the primary advantages of precision CNC machining is its ability to produce complex parts with high accuracy. The technology typically achieves tolerances of ±0.005 inches, which is crucial for sectors such as aerospace and medical devices, where precision is paramount.

Precision CNC machining has transformed custom parts production, delivering a range of benefits that modern manufacturers cannot afford to overlook. According to a 2021 report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2028, showcasing the growing reliance on this technology across various industries. One of the primary advantages of precision CNC machining is its ability to produce complex parts with high accuracy. The technology typically achieves tolerances of ±0.005 inches, which is crucial for sectors such as aerospace and medical devices, where precision is paramount.

In addition to accuracy, precision CNC machining offers significant efficiency gains. The rapid prototyping capabilities allow manufacturers to reduce lead times drastically, with some estimates suggesting a reduction of 30% to 50% in production time compared to traditional machining methods. Furthermore, the automation involved in CNC operations minimizes human error and enhances consistency, contributing to a reduction in waste and production costs. A study from the Manufacturing Institute found that 70% of manufacturers believe CNC machining is essential to maintaining competitive advantage in an increasingly demanding market. This technology not only optimizes the production process but also elevates the quality and reliability of custom parts, setting a new standard for modern manufacturing.

How Precision CNC Machining Enhances Product Quality and Consistency

Precision CNC machining plays a pivotal role in enhancing product quality and consistency in modern manufacturing. By leveraging advanced computer-controlled processes, manufacturers can achieve exceptional levels of precision that traditional machining methods cannot match. This high degree of accuracy ensures that each part produced meets stringent specifications, leading to fewer errors and better overall product performance. With the ability to replicate complex designs without variation, CNC machining eliminates the inconsistencies that often plague mass production, resulting in higher-quality end products.

Moreover, the consistency achieved through precision CNC machining directly translates to improved reliability for consumers. When parts are manufactured within tightly controlled tolerances, the likelihood of defects diminishes significantly, fostering trust in the product’s quality. This reliability is particularly crucial in industries such as aerospace and automotive, where even minor inconsistencies can have severe safety implications. As businesses continue to prioritize quality and efficiency, investing in precision CNC machining becomes essential to maintain competitive advantage, satisfy customer expectations, and innovate in product development.

Economic Impact of Precision CNC Machining on Global Manufacturing Markets

The economic impact of precision CNC machining on global manufacturing markets is profound and continues to shape the industry's landscape. The global CNC machine market is projected to expand significantly, growing from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, at a compound annual growth rate (CAGR) of 9.9%. This robust growth underscores the increasing demand for precise and efficient manufacturing processes, enabling companies to enhance productivity while reducing costs.

Moreover, the rise of specific segments within the CNC machining field, such as the 5-axis CNC machining centers market, further illustrates this trend. This market is anticipated to see growth of USD 792.5 million from 2024 to 2028, driven largely by advancements in self-optimized machine cutting technologies and the integration of artificial intelligence. As manufacturers adopt these innovative technologies, they not only improve their competitiveness but also contribute to a significantly broader economic impact on global manufacturing markets, reflecting the transformative power of precision CNC machining in today's economy.

Future Trends: Innovations in CNC Machining Technology and Their Implications

The landscape of modern manufacturing is undergoing a significant transformation with the rise of precision CNC machining technologies. As industries increasingly adopt digital manufacturing solutions, the demand for high-precision and efficient production processes has surged. This shift is further propelled by the introduction of environmentally friendly machinery that offers cost-effective operational solutions, enabling suppliers to transition from conventional methods to automated systems. This automation not only enhances productivity but also reduces waste and energy consumption, aligning with global sustainability goals.

As highlighted in the recent "Yangtze River Delta Manufacturing Digitalization Construction Demand Side Market Research Report," the drive towards digital transformation in manufacturing is vital for the industry's future. Upcoming events like MIMF 2025 demonstrate the commitment to showcase innovative technologies that are reshaping smart devices and manufacturing processes. The continuous development of CNC machining technology will play a pivotal role in driving the industry forward, ultimately leading to new opportunities and advancements in various sectors reliant on precision engineering. The focus on integrating cutting-edge tools and methodologies lays the groundwork for a robust industrial future that embraces innovation and efficiency.

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

| Innovation Type | Description | Implication | Future Trend |

|---|---|---|---|

| Automation | Incorporating robotics and AI in CNC machining processes | Increased efficiency, reduced labor costs | Growth in automated systems |

| Advanced Materials | Use of lightweight, durable materials such as composites | Improved product performance and longevity | Innovation in material science |

| Cloud Computing | Utilizing cloud-based software for design and simulation | Enhanced collaborative capabilities | Expansion of Industry 4.0 technologies |

| 3D Printing Integration | Combining CNC machining with additive manufacturing | More complex designs and faster prototyping | Synergy between subtractive and additive methods |

| Smart Manufacturing | Integration of IoT devices in CNC machinery | Real-time monitoring and predictive maintenance | Focus on digital twins and smart factories |