Tool deflection is a subtle yet significant challenge in CNC machining that can result in poor surface finishes, inaccurate cuts, and even tool breakage. The good news is that with the right techniques, you can manage it effectively. Whether you’re an experienced machinist or a beginner, these 10 tips will help you reduce tool deflection and ensure precision with every cut.

#1 Use the Right Tool Material

The material of your cutting tool can play a vital role in its strength, durability, and overall performance. If the tool does not possess a rigidity sufficient to withstand machining, it may flex or vibrate during cutting, resulting in poor surface finishes, reduced accuracy, and/or even the potential for tool breakage.

To avoid the above problems, it is imperative to choose high-strength tool materials. Carbide, for instance, usually becomes the first choice because it is harder and more wear-resistant than high-speed steel (HSS) and many others. Carbide tools retain their sharpness longer, endure higher cutting speeds, and cut machining time which improves efficiency and lower costs.

Choosing the right material for your tool ensures a more stable cutting process, more accuracy, and longer tool life.

#2 Optimize Tool Geometry

The shape and size of the cutter are important in determining machining accuracy and stability. The longer and thinner the tool, its chances of bending and vibrating are much more pronounced. It can lead to an uneven surface finish and improper precision. Generally, the use of shorter tools with larger diameters wherever possible is preferred.

Shorter tools are inherently stiffer and more stable, thus minimizing burring or bending during cutting. The larger diameter also imparts a stable strength that helps in reducing flexing under pressure. Just by choosing the right tool geometry, you can increase the performance of your cutting operations, prolong your tool life, and achieve better machining results.

#3 Adjust Cutting Parameters

It is important to achieve a balanced setup of cutting speed, feed rate, and depth of cut to attain the best results in machining. Failure to make an adequate tool change in these settings results in tool deflections, vibration, poor precision, and a rough surface finish.

As these parameters are modified, try to minimize the degree of deflection. One way to do this would be keeping the depth of cut limited or slowing the feed to maintain stability. Setting an optimum cutting speed permits a fast rate of material removal, but it ensures that undue stress is not put on the cutting tool. With the right tuning of these factors, the required precision can be enhanced, tool life extended, and finishing work smoother and with greater consistency.

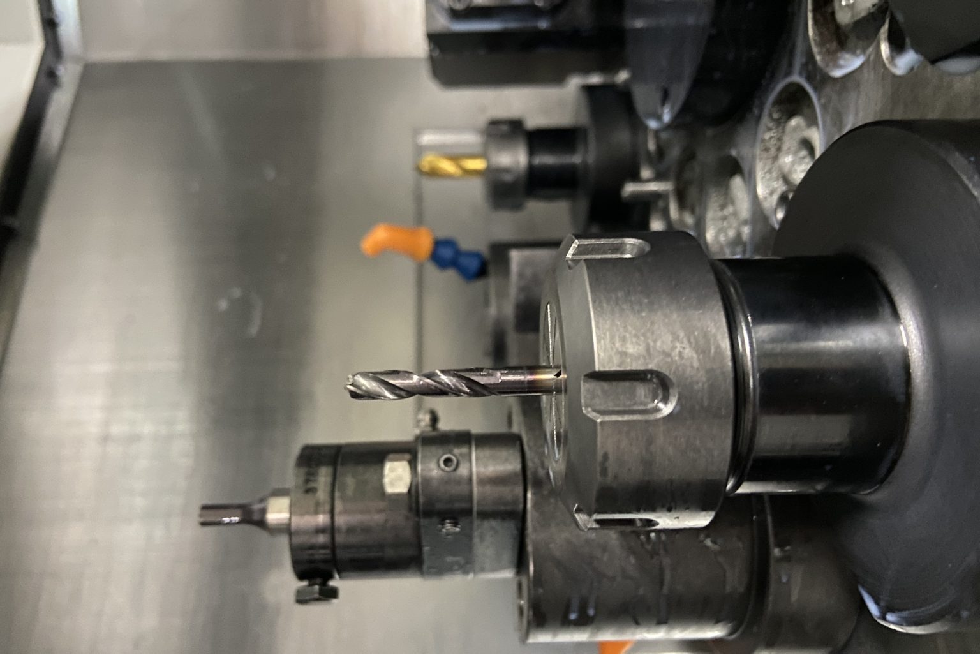

#4 Use Proper Tool Holders

A good tool holder is just as important as the cutting tool. It keeps the tool stable, hence reducing vibrations and improving precision during machining. A loose tool will move slightly, resulting in poor surface finishes and tool breakage.

High-quality tool holders like shrink-fit or hydraulic holders will give the best results. They have better grip, better stability, and less runout-a small misalignment that can affect the accuracy. The proper tool holder allows the smoothest cutting, maximum tool life, and better quality machining.

#5 Reduce Overhang Length

Longer cutting tool projection beyond the holder means that it is more likely to deflect and vibrate during the process of machining. Deflection is often cited as a great contributor to poor accuracy, rough surface finishes, or possibly tool breakage.

In the spirit of stability, always aim for the shortest overhang. Shorten working length to the least needed for each specific tool, and hold it firmly in the spindle. If a long reach is desired, choose a more rigid tool material or a tool holder that can maintain stability. Less overhang makes tooling more precise, enhances tool life, and guarantees smoother machining.

#6 Employ Support Structures

When machining very long or thin parts, they may move or vibrate, resulting in poor accuracy and rough finishes. To counter this, support structures like steady rests or tailstocks help to hold a workpiece firmly in place. Those supports should be positioned as closely to the cutting area as possible.

Regularly check these supports to ensure that they provide stable and even support. Appropriate supports stabilize the machining, increase tool life, and improve the surface finish of the part.

#7 Use Proper Clamping Techniques

A loosely placed workpiece can move or vibrate while being milled, resulting in inaccuracies, a rough finish, or even damage to the workpiece. This is why fastening should be done properly for the rest of the procedure to run smoothly with accurate cutting.

Choose clamps and fixtures designed to hold the workpiece still. Use of vise clamps, T-slot clamps, and vacuum fixtures assist in holding the material in place. The clamping force should be medium enough to hold the workpiece from moving but not so great as to distort it. Proper clamping provides better machining, reduces wear on cutting tools, and improves efficiency.

#8 Choose the Right Machining Strategy

The way you approach machining a part can significantly impact both tool performance and the quality of the finished product. Certain strategies can help minimize tool stress, enhance efficiency, and prolong tool life.

For instance, trochoidal milling employs a circular cutting motion that reduces heat and stress on the tool, allowing it to last longer. Techniques such as step-down (gradually cutting deeper in layers) and step-over (moving sideways in smaller increments) help to distribute cutting forces more evenly, which prevents tool breakage and enhances surface finish.

By selecting the appropriate CNC machining strategy, you can achieve smoother cuts, decrease tool wear, and boost overall productivity.

#9 Maintain Tool Sharpness

A dull cutting tool can cause more hurdles than one can imagine. Once a tool gets dull, cutting takes more effort, which means that your tool runs the risk of bending, becoming less precise, and that it may also break the workpiece.

Consequently, it can alleviate lots of these matters if one maintains a set regimen for sharpening and/or replacing the tools before they become too dull. Sharp tools make cleaner cuts and would, therefore, not strain the machine, thus resulting in less wear and tear on both the tool and the workpiece. The better care you take of your tools, the better they perform, allowing you to save a lot in the long run.

#10 Invest in High-Quality Machines

The machine by itself is very important for the performance of tools. If a machine lacks rigidity, poorer accuracy and finishes are consequences of its vibrations that arise, subsequently resulting in earlier wear of tools. The machinable, high-quality CNC machines point to better stability and smoother, more accurate cuts.

Though an advanced CNC may cost somewhat more than its predecessor, it pays for itself over the years with an improved degree of efficiency, quality of parts, and blunt breaks on tooling. Buying a high-quality machine means fewer mistakes and reduced downtime, builds productivity, and saves money along with the loss of work time.

Conclusion

What it’s getting at is that smart decisions regarding tooling, parameter settings, and reliance on tooling would eliminate deflection as a major machining error. Any little changes made to reduce overhang, keep the tool sharp, and the usage of quality tooling help in huge amounts to improve accuracy, surface finish, and tool life.

In keeping with these ten tips, modulation of the state of machines, reduction of costly mistakes, and fruitful productivity of the CNC machining setups are applicable. When fine-tuning the process or upgrading equipment, devoting attention to deflection control will undoubtedly increase efficiency and part quality.

Improve accuracy and effectiveness through MDA’s CNC machining. Take your manufacturing to new heights – Consult with our experts.

|